INTRODUCE:

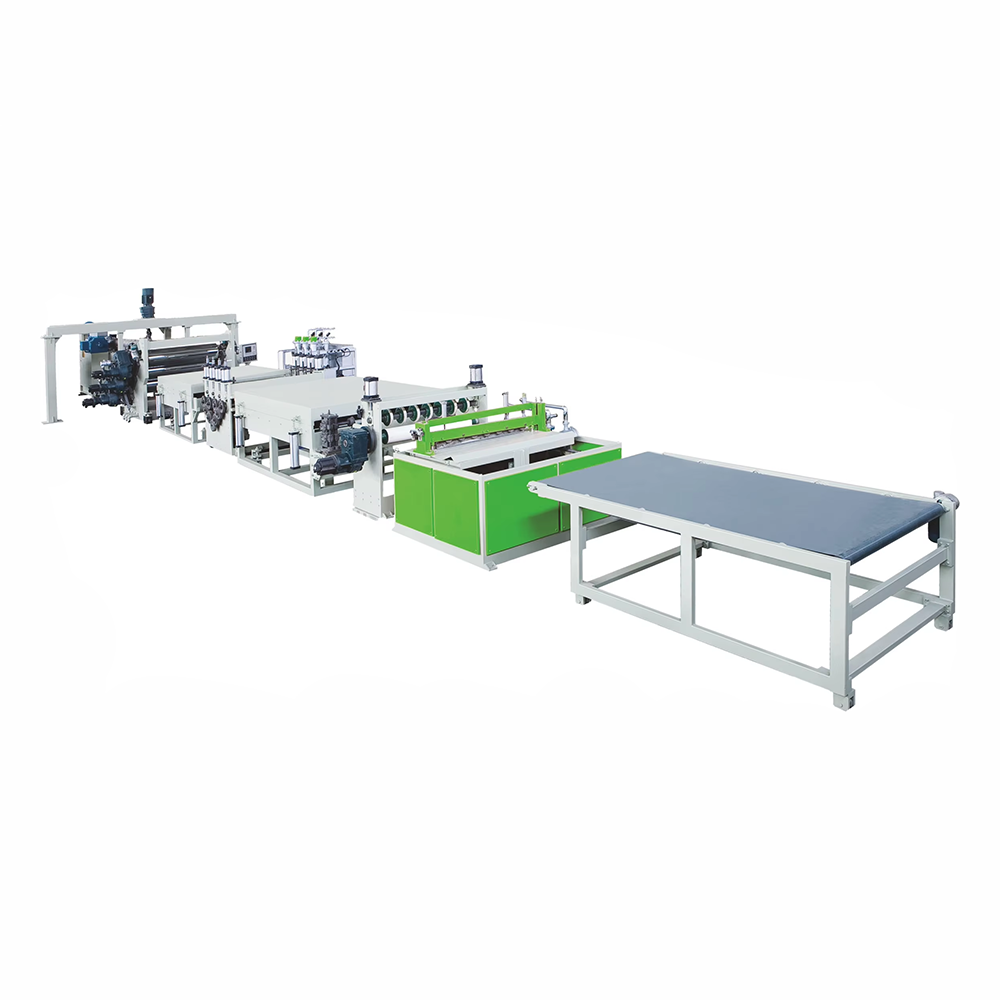

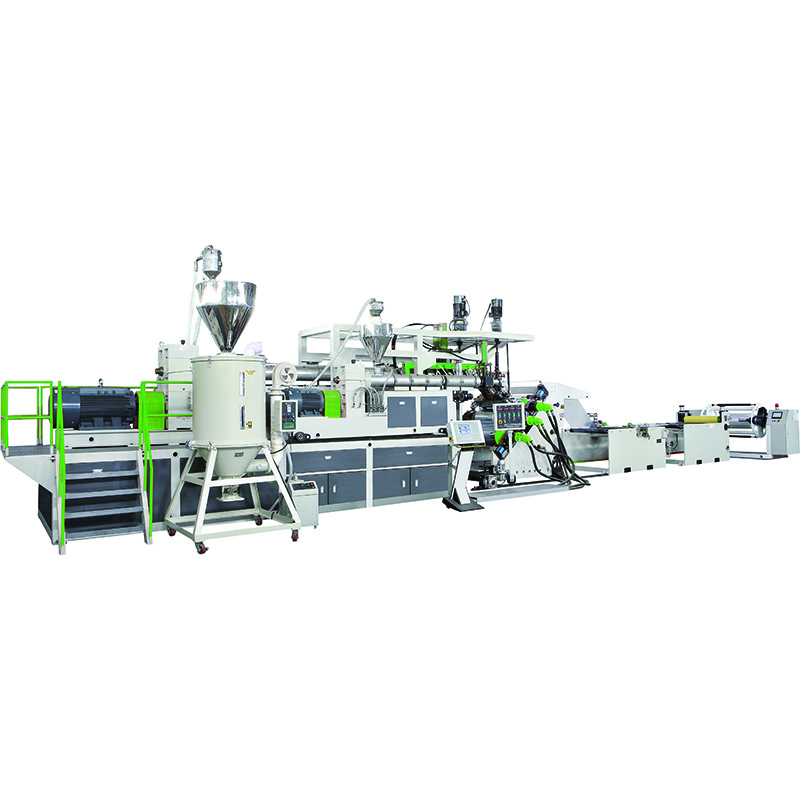

The POE film production line is the equipment used to make the POE film, and it plays an important role in the solar photovoltaic industry. This equipment usually consists of multiple parts, including feed system, extruder, mold, flow extension machine, roller cooling system, tractor, winder, etc. Among them, the extruder is the core component of the whole equipment. It heats and melts the POE material through high temperature and high pressure, and then squeezes it through the mold, and then cooling the machine. After a series of processing and testing, it finally rolls the finished product through the winding machine.

The working principle of POE film extrusion line mainly involves the melting, extrusion, cooling, molding and winding of raw materials.

- The production line will add POE resin and other additives to the melting system. Here, POE particles are heated and melted through a melter to form a uniform melt. Meanwhile, the melt mixing equipment ensures the uniformity of the melt.

- The molten POE melt is sent into the extruder. Extruder is the core equipment in the production line, which consists of hopper, screw, screen, extrusion head and cooling roller. In the extruder, the screw will press and plasticize the melt, and then squeeze the melt into a film through the extrusion head. The extruded film then enters into the cooling system.

- The cooling system is mainly composed of cooling roller and roller cooling device. The cooling roller is used to cool and cure the hot film while adjusting the thickness and width of the film. The roller cooling device is responsible for controlling the temperature of the cooling roller to ensure that the film has sufficient cooling effect. During the cooling and curing process, the POE film gradually forms its specific structure and properties.

- After the cooling system, the film has reached the required hardness and stability, and can be processed for subsequent processing and treatment.

- Finally, the production line will smoothly transport and roll up the cooled and cured POE film through the tractor and the winder to facilitate subsequent storage and transportation.

Features of the POE adhesive film production line:

Efficient automation: POE photovoltaic film production line adopts advanced automation technology to realize the automatic operation of the whole process from raw material input to finished products out of the warehouse, improving the production efficiency and quality level.

Accurate control: The production line is equipped with accurate temperature, pressure, speed and other parameter control system, through PLC and other automatic controller for data transfer and processing, to achieve high precision, stable and reliable production process.

Energy saving and environmental protection: The production line adopts advanced energy saving technology and environmental protection materials, which effectively reduce the energy consumption and the impact on the environment.

High quality output: POE photovoltaic film production line to high standard quality requirements as the goal, after strict process and quality testing, to achieve the high quality product output to meet the technical standards and customer needs.

Reliable stability: the production line equipment is made of high-quality materials and process, with the characteristics of long life, high stability and low maintenance cost, to meet the long-term and stable production needs of customers.

Characteristics of the POE film:

POE photovoltaic film is a common photovoltaic cell packaging material. Its main features include:

1,Good weather resistance: POE photovoltaic film has excellent weather resistance and can maintain long-term stability under stimuli.

Reduce air pollution: Compared with other materials, POE photovoltaic film has lower volatility, helping to reduce air pollution.

2,Good UV performance: POE photovoltaic film has high UV resistance, can effectively prevent ultraviolet damage to the circuit board.

3,Easy to process: POE photovoltaic film can be processed quickly in conventional processes and does not require expensive equipment or special skills.

4,Safety and environmental protection: POE photovoltaic film does not contain lead and halogen compounds, comply with ROHS and REACH environmental standards and EU regulations.

5,High diffusion transparency: POE photovoltaic film also has a high diffusion transparency, which can increase the distribution of sunlight after incident, and improve the efficiency of photovoltaic cell modules.

Application:

Photovoltaic field: POE film is the most widely used in the photovoltaic field, mainly used in the packaging of solar panels, which has excellent weather resistance, PID resistance and water vapor barrier resistance.

Automotive field: Under the trend of automotive lightweight, POE materials are widely used in automotive parts, such as bumper and airbag boxes, because of their low density and excellent weather resistance.

Packaging field: The high strength and good flexibility of POE film make it an important material in the packaging industry, widely used in the packaging of food, medicine and other industries.

Construction field: In the field of construction, POE film is used for waterproof coil, pipe and other aspects, showing a good application prospect.

Agricultural field: POE film is mainly used for agricultural covering film in the agricultural field, such as greenhouse film, fruit and vegetable packaging film, etc., with good weather resistance, aging resistance and light transmittance.

Medical field: In the medical field, POE film is used in the packaging of medical devices, such as medical dressings, surgical supplies, etc., which has the characteristics of soft, transparent, easy to clean, and is suitable for bandaging, dressing, surgery and other fields.

Industrial field: POE film is widely used in waterproof, dustproof and other aspects in the industrial fields, such as battery packaging, wire insulation, building materials waterproof, etc., to meet the needs of different industrial products.

New energy field: POE film is also used in cover materials of solar panels, has good light transmittance, weather resistance and chemical corrosion resistance, help to improve the power generation efficiency and service life of solar panels.

Building insulation materials: POE film is also widely used in building insulation materials, such as roof insulation, external wall insulation, etc., with excellent insulation and weather resistance.