(一) Production process

- Pretreatment of raw materials

(1)Raw materials should be strictly screened before entering the extruder. For PC raw materials, the optical purity should be checked to ensure that the corrugated sheets produced have high light transmittance.

(2)Depending on the application, specific additives are added. For example, in the production of corrugated sheet for outdoor use, an appropriate amount of ultraviolet absorber will be added to the raw material to prevent the sheet from aging in the sun over a long period of time.

- Extrusion molding

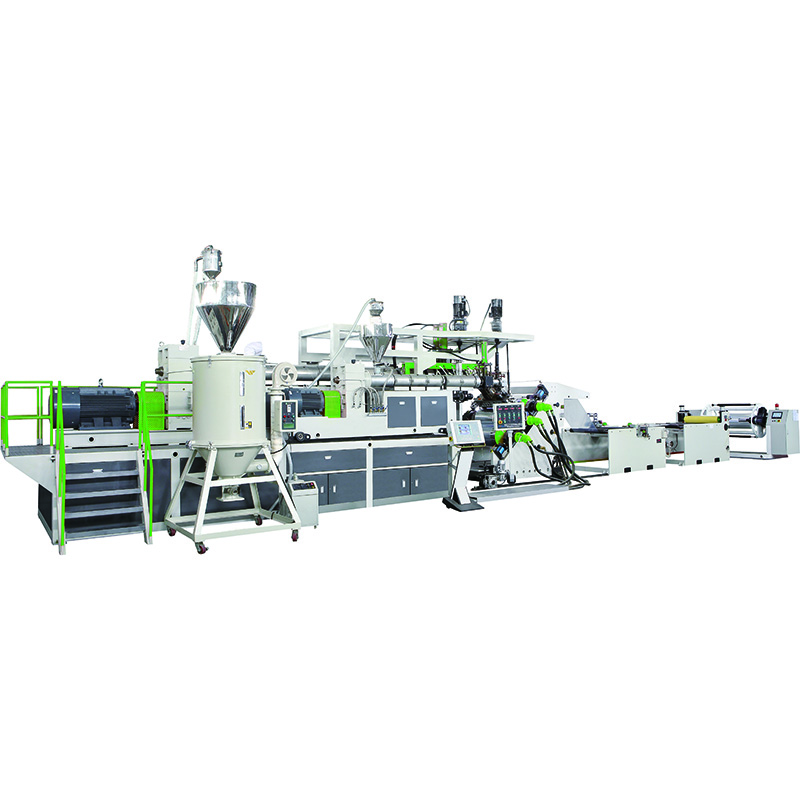

The raw material enters the twin – screw extruder through the high – precision loss – in – weight feeder.

(1)The control of barrel temperature is very critical. For PC, the barrel temperature is generally between 240 – 280°C, and slightly higher near the die head to ensure the fluidity of the PC melt. The barrel is equipped with several temperature sensors to provide real – time feedback of temperature data, and the heating and cooling devices are precisely adjusted by an intelligent control system to ensure that the temperature fluctuation is controlled within ±1℃.

(2)The melt from the extruder enters the special die head for corrugated sheet. The internal flow channel of the die head is specially designed with streamline structure. The corrugated molding part of the die head consists of several high – precision inserts, which can be quickly adjusted by replacing the inserts, such as wave height, wave pitch and width of the corrugated plate, to meet the customized needs of different customers.

- Cooling and molding

(1)The extruded corrugated sheet firstly enters into the air – cooling area, the air – cooling can make the surface of corrugated sheet cool down quickly, and set the shape initially, and prevent the internal stress caused by too fast cooling.

(2)Then the corrugated sheet enters the water cooling area, which adopts a circulating water system, and the water temperature is precisely controlled at 10 – 20℃ by a water chiller. After water cooling, the shape and size of the corrugated sheet are basically stabilized.

(3)After cooling, the corrugated board will enter the shaping device, which consists of several sets of shaping rollers that press up and down against each other, and the surface shape of the shaping rollers is precisely matched with the corrugated shape of the corrugated board. By adjusting the pressure between the shaping rollers, the thickness of the corrugated board and the regularity of the corrugated shape can be precisely controlled, and the pressure control accuracy can reach ±0.05MPa.

- Cutting and post – processing

(1)After shaping, the corrugated sheet is pulled out by the servo motor – driven traction device at a constant speed, and the traction speed can be precisely adjusted between 0.5 – 5m/min according to the requirements of the production process.

(2)The corrugated sheet is cut by high – precision flying saw according to the set length. The saw blade of the flying saw is made of hard alloy, the rotating speed is up to 3000 – 5000rpm, and the cutting precision can reach ±0.5mm. When cutting, the feeding speed of the flying saw and the traction speed are matched precisely, which ensures the cutting process to be smooth, and the cuts to be neat and tidy.

(3)The edges of the cut corrugated sheet will be sanded.

(二) Equipment composition

- Extruder The extruder is the core of the production line. It consists of a feed hopper, a barrel with a screw, and a heating and cooling system. The screw is designed to efficiently convey and mix the raw material, and the heating and cooling system allows for precise temperature control during the extrusion process. The extruder is usually equipped with an advanced control system that monitors and adjusts extrusion parameters in real time.

- Die head The die head is critical to the formation of the corrugated sheet shape. It is made of high – quality steel with a smooth surface and a precise corrugated pattern. The die head can be adjusted to produce corrugated sheets with different wave heights, spacing and widths. Some die heads are also designed with a quick – change feature to increase productivity.

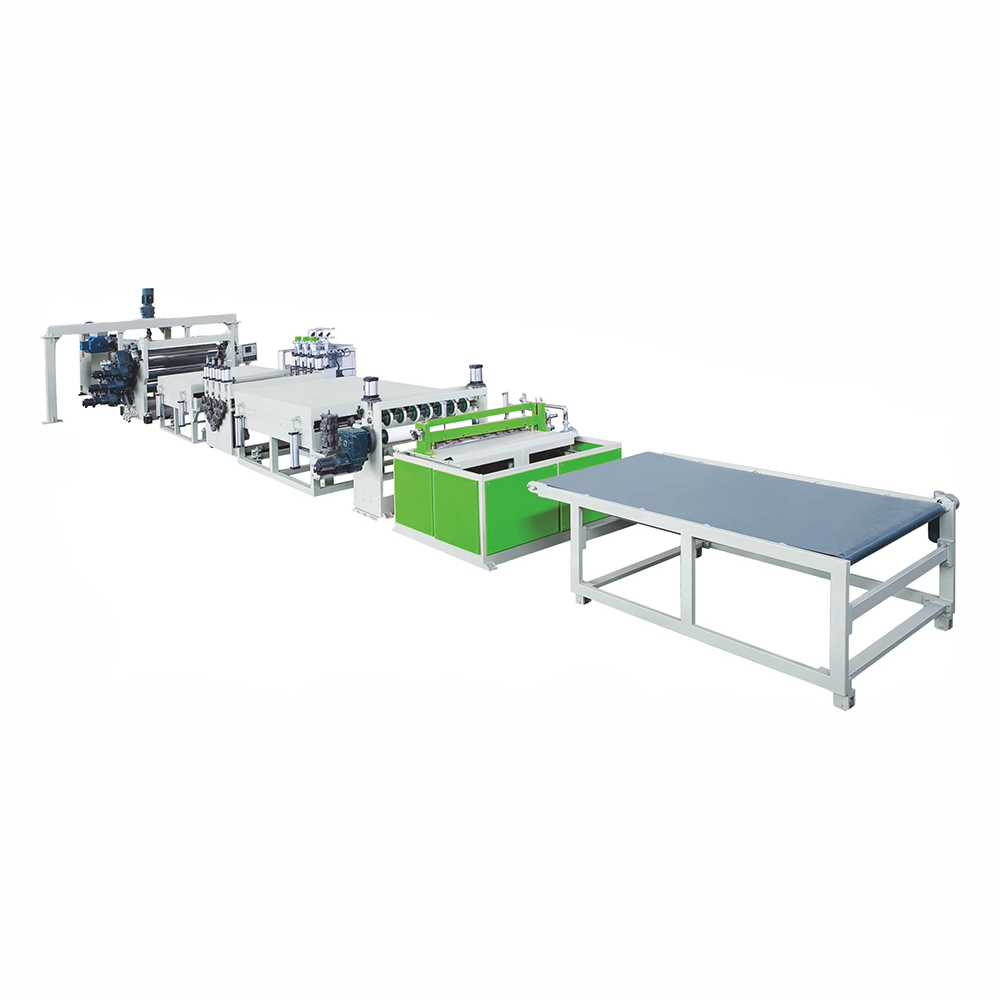

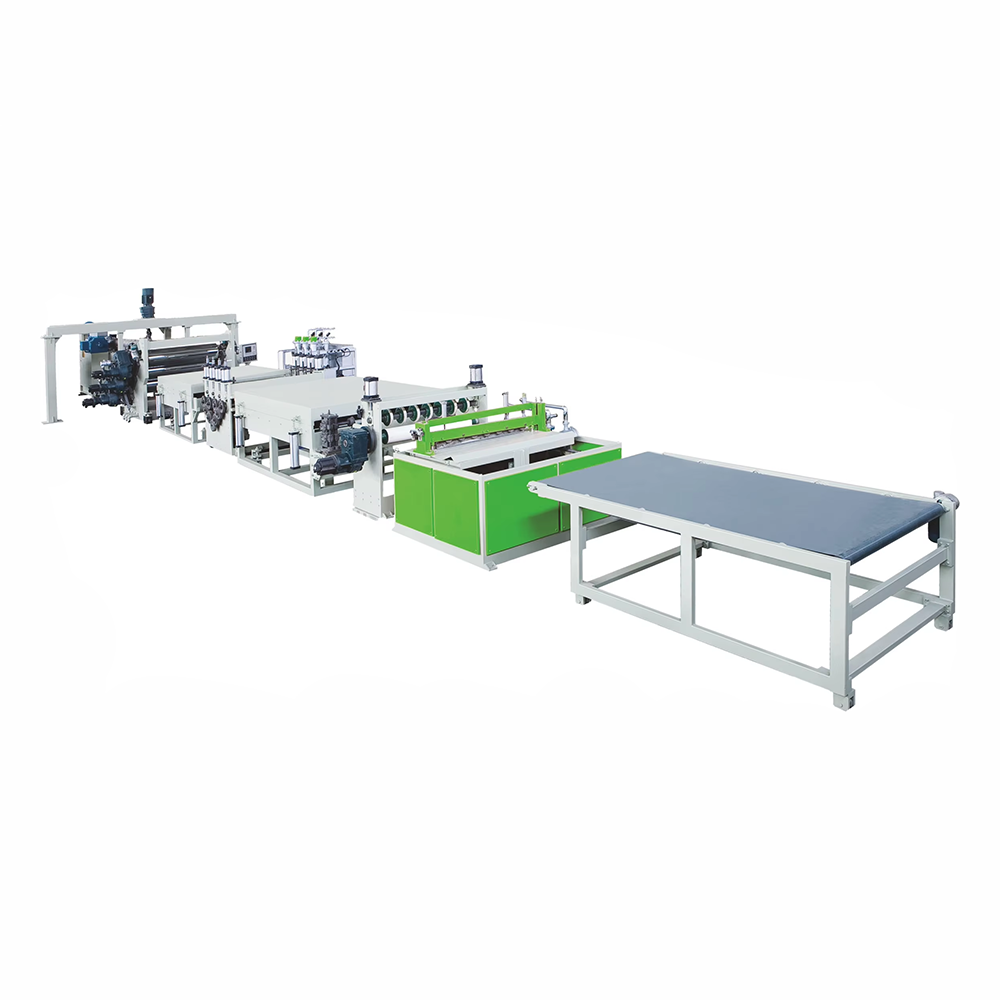

- Cooling Calibration System

The cooling calibration system consists of cooling fans, water – cooling channels, calibration rollers and dies. The cooling fan provides initial air – cooling and the water – cooling channels provide further cooling to ensure uniform cooling of the sheet. The calibration rollers and molds are used to accurately shape and size the corrugated sheets.

- Cutting equipment

Cutting equipment is specially designed for corrugated sheets, including circular saws or specialized cutting machines. These cutting machines are equipped with high – precision positioning systems to ensure accurate cutting lengths. Some cutting machines also have automatic feeding and cutting functions to increase production efficiency.

- Product Classification

- PC corrugated sheet

(1)Architectural lighting: PC corrugated sheet is widely used in architectural lighting, with good impact resistance and high light transmission rate, commonly used in large commercial buildings, exhibition halls and airport terminal lighting roof.

(2)Greenhouse: In agricultural greenhouses, PC corrugated sheet is an ideal covering material. It can transmit UV rays that are beneficial to plant growth and promote plant photosynthesis. It also has good heat preservation performance, which helps to extend the growth cycle of crops and increase the yield.

PC-Optic-Sheet-Extrusion-Line.jpg)