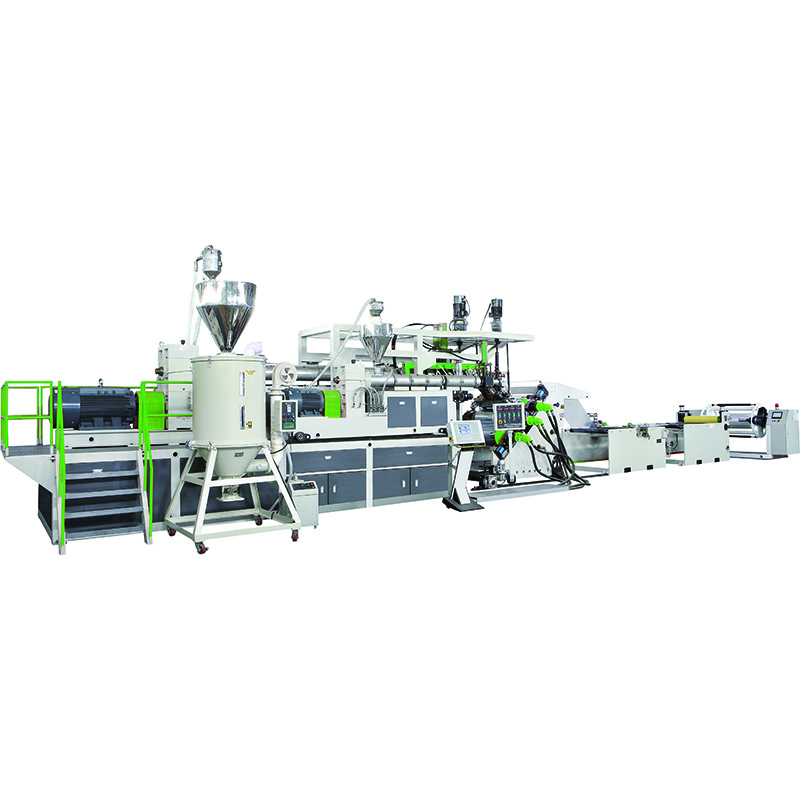

PVC transparent sheet and hard sheet is a top solution. It satisfies the demand of modern industrial, commercial, and packaging applications. This advanced machine is designed by heart; it has accuracy, durability, and efficiency, and it is the most important tool to produce high-quality transparent and hard PVC sheets for manufacturers.

Features and functions

- Multifunctional design: it can produce transparent and hard PVC sheet with smooth and uniform surface.

- High accuracy and stability: an advanced temperature control system and screw design can make sure of consistent thickness and optical clarity.

- Save energy: equipment with high-efficient motors and optimizing heating zones in order to reduce energy consumption.

- Easy operation: The user-friendly PLC control system has an intuitive interface in order to monitor and adjust.

- Customize option: mold design can meet clients different requirements.

Problems solved

plastic extrusion line solved few challenges that manufacturers were facing.

Consistent thickness and clarity: eliminate the difference in sheet thickness and improve the transparency of products.

Reduce the waste of materials: accurate control minimizes waste and reduces production costs.

Environmental compliance: processing environmental and recycled materials, obey green manufacturing standards.

User Experience

User Experience

The system is specially designed for seamless operation. From installation to maintenance, each aspect reduces downtime of the machine and improves efficiency. Operators benefit from direct control and real-time monitoring in order to ensure product quality.

Target Audience

PVC transparent sheet and hard sheet extrusion line is very suitable for packaging. Manufacturers need high-definition sheets for blister packaging; industry suppliers need durable sheets for architecture or signs. Furniture and decoration manufacturers are looking for rigid and multifunctional materials.

Usage Condition

This plastic extrusion line is suitable for all kinds of applications, including:

Blister packaging: apply for the transparent sheet of medicine, food, and consumer goods packaging.

Architecture materials: apply for durable sheets for partitions, siding, and roofing.

Decoration application: apply for sheets for furniture facings, signs, and advertising boards.

Technical Details

Type of extruder: twin-screw extruder, equipment with the special design screw for PVC processing

Output capacity: 200-800kg/h, depends on model configuration

Sheet thickness: 0.2–3.0 mm; it can choose to upgrade to thicker sheets

Width range: up to 2000mm

Cooling system: high efficiency multigrade cooling, cooling and solidification fast

Optional attachment: Inline Lamination Unit, cutting and slitting systems and surface laminate roller

Supporting Services

Installation and Commissioning: Installation and training on site ensure smooth operation

Maintaining service: regular maintenance plan can make machine keep the best condition

Spare parts supply: parts replacement service is fast and reliable

Technical support: 24/7 online and offline technical assistance

Pricing and Promotions

Competitive Pricing: Starting at $45,000, offering exceptional value compared to similar products in the market.

Discounts: Limited-time offers of up to 10% on bulk purchases or early orders.

Financing Options: Flexible payment plans to accommodate different budget requirements.

Value Proposition and Competitive Edge

Cost-Effectiveness: Superior output quality at a lower production cost compared to competing models.

Reliability: Built with high-quality components to ensure long-term performance and reduced maintenance.

Flexibility: Ability to produce a variety of sheet specifications with a single line.

Sustainability: Designed for energy efficiency and compatibility with recycled materials, aligning with eco-conscious manufacturing trends.

Investing in PVC transparent sheet and hard sheet extrusion lines not only ensures the advantage of quality and productivity but also ensures savings for a long time and is suitable for market needs. The extrusion line, due to its advanced functions, customized service, and competitive price, is a solid choice for companies aiming to expand scale and innovate in the PVC sheet industry.

PC-Optic-Sheet-Extrusion-Line.jpg)