Why choose PP?

1.Chemical dependability: PP material has great compound security and can endure the disintegration of destructive substances, for example, corrosive and salt, making it reasonable for use in different conditions.

2.Heat obstruction: PP material has high intensity opposition, can keep up with solidness at high temperatures, and isn’t handily distorted or liquefied.

Lightweight and High Strength: PP material has a lower thickness, is lightweight, yet has high strength, making it beneficial in assembling lightweight and high-strength items.

3.Easy to process: PP material is not difficult to process and shape, and can be fabricated in different shapes and sizes through cycles, for example, blow shaping, infusion shaping, expulsion, and so on.

4.Environmentally agreeable and recyclable: PP material can be reused and reused, meeting natural prerequisites and advancing asset preservation and reusing. one

What it can be used to make?

1.Packaging industry: PP sheet is ordinarily utilized in the creation of vacuum shaped items like food plate, food plate, and food boxes because of its high straightforwardness, great surface gleam, and high sturdiness. These items are harmless to the ecosystem, yet additionally can actually show items and further develop item quality.

2.Stationery industry: PP sheets can be utilized to make different writing material items, for example, organizers, document packs, business card boxes, attachés, pencil cases, and so on. These items ordinarily require a specific level of strength and style.

Gift industry: PP sheets can likewise be utilized to make gift boxes, cosmetics boxes, gift sacks, purses, and other gift bundling, which ordinarily require an appealing appearance and great defensive execution.

3.Food industry: As PP sheets satisfy food testing guidelines, they can be utilized to make food contact items, for example, placemats, liners, drinking cups, bowls, treats boxes, and so on.

4.Lighting industry: PP sheets can likewise be utilized to make lighting items like lampshades, using their phenomenal intensity opposition and straightforwardness.

5.Electronics industry: In the gadgets business, PP sheets can be utilized to make electronic sandwich boards, bundling boxes, and so forth, to shield electronic parts from harm.

6.Shoe and clothing industry: The use of PP sheets in the shoe and dress industry incorporates the creation of attire boxes, purses, craftsmanship sheets, and so on, assisting with securing and show items.

7.Other applications: PP sheets can likewise be utilized to make grocery store pennants, baggage labels, street signs, drawers, waterproof shell bundling boxes, photograph outlines, and different items to address the issues of various events. twelve

In synopsis, PP plastic sheets assume a significant part in different enterprises because of their numerous benefits. From bundling to writing material, from food holders to electronic extras, the use of PP sheets is universal.Extrusion process

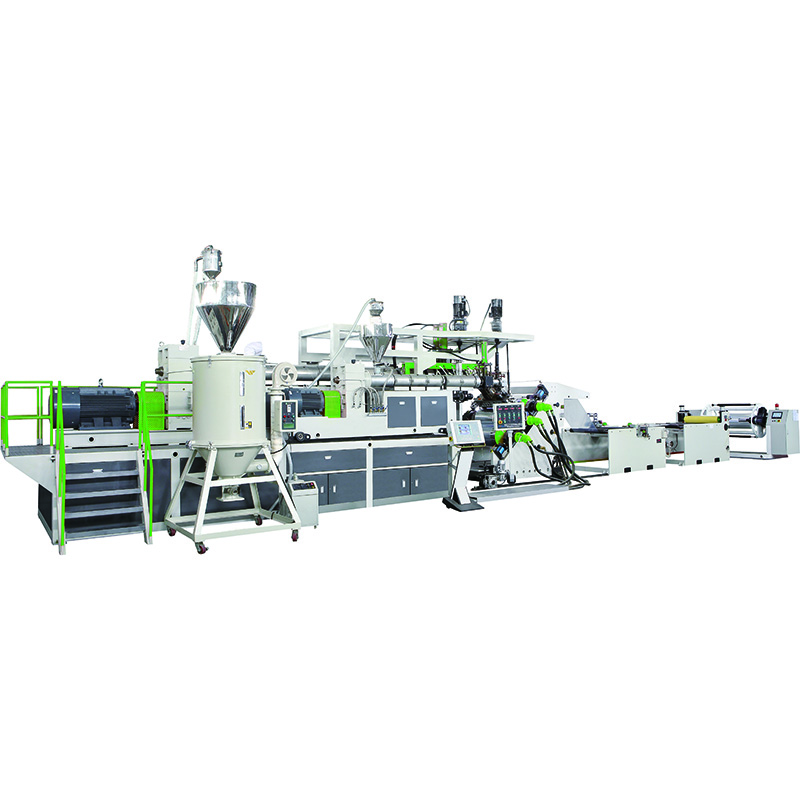

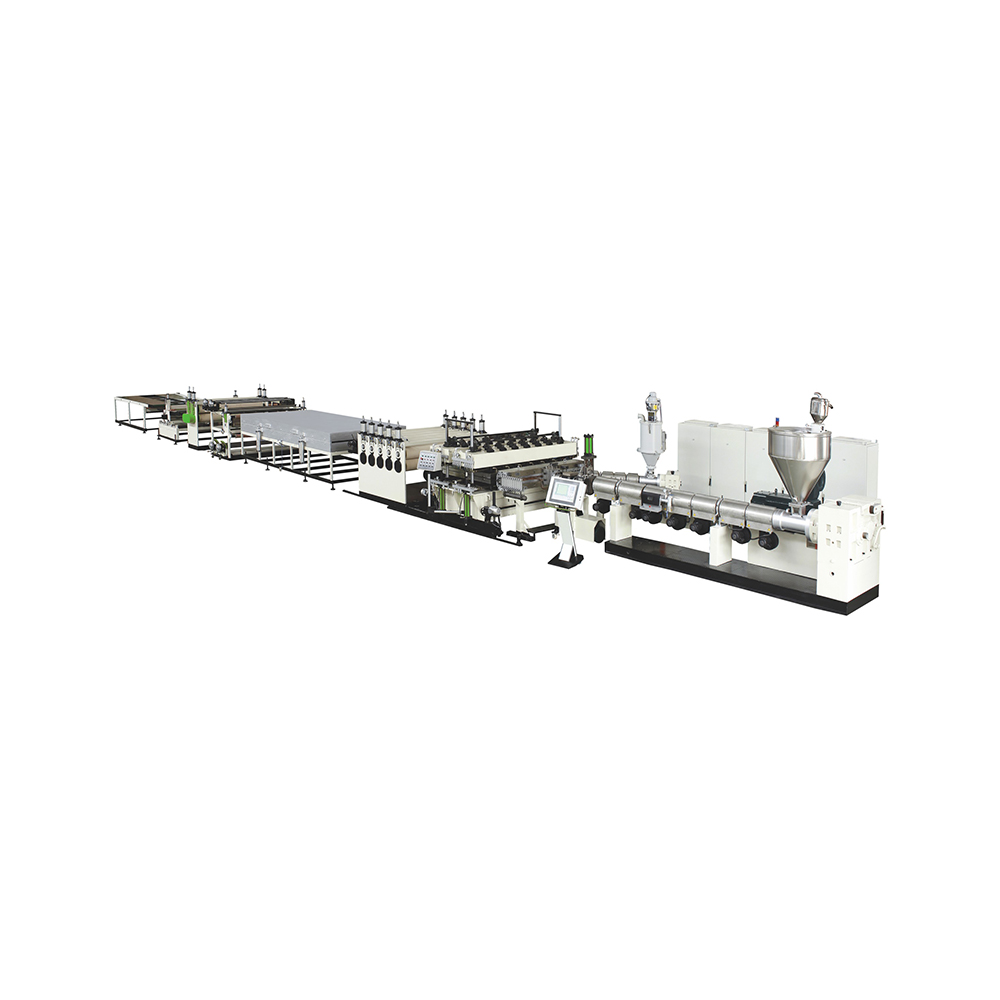

1.Raw material stock framework: including unrefined substance stockpiling hardware and conveying gear, used to move PP particles and other unrefined substances to the creation line to guarantee stable inventory of unrefined substances.

2.Extruder: As the center gear in the creation line, it warms and dissolves the natural substances through the pivot and shearing of the screw, and expels them into a nonstop soften. The extruder can be a solitary screw or numerous screws, contingent upon creation prerequisites and unrefined substance qualities.

3.Molds and multi-facet supply frameworks: Molds are utilized to shape expelled liquefy into sheets of explicit shapes and sizes. The multi-facet supply framework is utilized to accomplish the creation of multi-facet sheets, by joining various extruders and molds to stack various varieties, materials, or elements of liquid materials together.

4.Compression and cooling framework: The calender is utilized to level and smooth the outer layer of the sheet, making it smoother. The cooling gadget quickly lessens the temperature of the sheet material through air or water cooling, permitting it to set and shape.

5.Traction and winding framework: The footing machine is utilized to ceaselessly take out the packed and cooled sheets, keeping up with their strain and solidness. The winding machine winds the took out sheet into a roll for ensuing stockpiling and transportation.

6.Electrical control framework: answerable for the electrical control and mechanization activity of the whole presentation line, including temperature control, speed guideline, issue identification, and different capabilities.

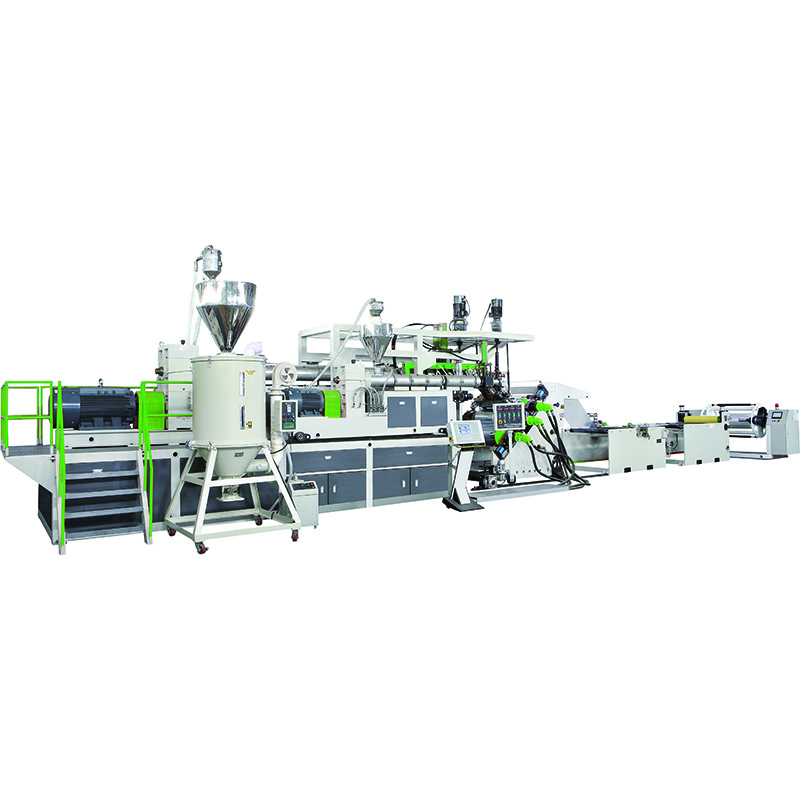

Equipment features

1.Compact construction and superb execution.

2.The screw and barrel are made of excellent nitrogen treated steel and covered with compound on a superficial level, guaranteeing the toughness and creation productivity of the gear.

3.The shape configuration is steady, the expulsion is steady, and the result is high.

4.The cooling framework takes on air cooling strategy to guarantee quick cooling of the sheet and further develop creation productivity.

5.Suitable for different plastic materials like PP, PE, PS, ABS, and so on.

6.It can create single-layer or multi-facet sheets, broadly utilized in fields, for example, food bundling, writing material, announcements, and so on.

Plastic extrusion and injection molding

| Plastic extrusion | injection molding | |

| Production efficiency | Continuous process, high output, suitable for large-scale production | Shorter cycle, suitable for small batch and complex shape production |

| Product shape | Suitable for producing 2D products | Suitable for producing 3D products |

| Material Applicability | Suitable for thermoplastic materials | Suitable for thermoplastic and thermosetting plastics |

| production costs | Low | High |

plastic extrusion: what is it? how does it work?

The expulsion strategy for a plastic extruder for the most part alludes to dissolving plastic at a high temperature of around 200 degrees, and the liquefied plastic is then framed into the ideal shape while going through a shape. Expulsion forming requires a profound comprehension of plastic properties and rich involvement with shape plan, and is an embellishment technique with high specialized necessities.

1.Plastic expulsion initially sends plastic particles or powder into a warming bucket.Then, the barrel step by step melts and packs the material through the pivoting screw. Liquid plastic is constrained through trim molds.

Then, the cooling framework quickly hardens them into a persistent shape. 2.Then, the foothold gadget pulls away the expelled plastic to keep up with consistency in shape and size. Contingent upon the reason, the item can be cut into the ideal length or moved into a roll.

3.Finally, a few expelled items might require extra cycles like printing or punching. Plastic expulsion initially sends plastic particles or powder into a warming pail. Then, at that point, the barrel bit by bit melts and packs the material through the turning screw. Liquid plastic is constrained through trim molds. Then, the cooling framework quickly cements them into a consistent shape. The foothold gadget pulls away the expelled plastic to keep up with consistency in shape and size.

4.Depending on the reason, the item can be cut into the ideal length or moved into a roll. At long last, a few expelled items might require extra cycles like printing or punching.

Related help

Our mechanical assurance period is a year. During this period, accepting there is any mechanical damage, the dealer will really take part and answer quickly in something like 6 hours to carrier freight the normal parts to the clients up the creek without a paddle. Purchasing gear goes with lifetime guiding organizations, and our master trained professionals and architects will continually give you the most master organizations and opinions.

Other assistance

It also integrates the arrangements and fix organization of kinds of single-screw, twofold screw, chamber, plastic sheet/plate pass on, screen transformers, distributer, reflect surface roller and bloom plan roller.

Purchase guide

In case you are a novice in the plastic extrusion industry, benevolently counsel our client care personnel first. We will help you with talking with engineers for nuances. Let us in on your viewpoints and ends on the new business, and we will give you some limit thoughts to additionally foster your prohibitive field-tried procedure. Directly following sending it to you for assertion, we will give you the best quotation.

Expecting that you have been significantly drawn in with the plastic extrusion industry for a seriously prolonged stretch of time, sympathetically talk with us about the nuances of the plan considering the limit ends given by your originators. Our client help staff will really talk with the engineers and complete the solution in something like one day before sending it to you for confirmation. After confirmation, we will outfit you with the best quotation.

Expecting to spread out long stretch agreeable supportive relationship with every single person who has a relationship with DWELL.