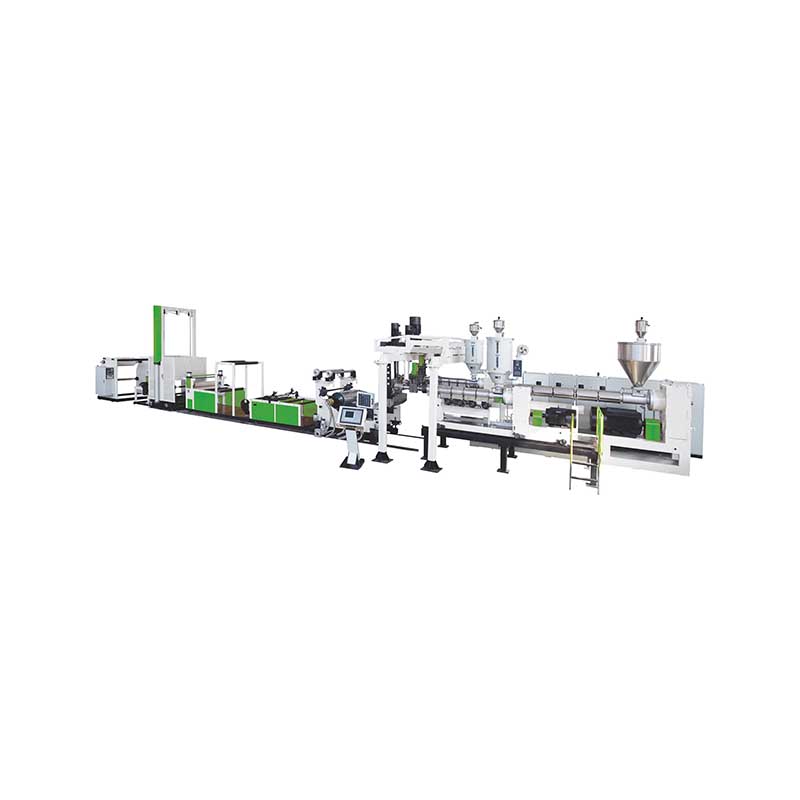

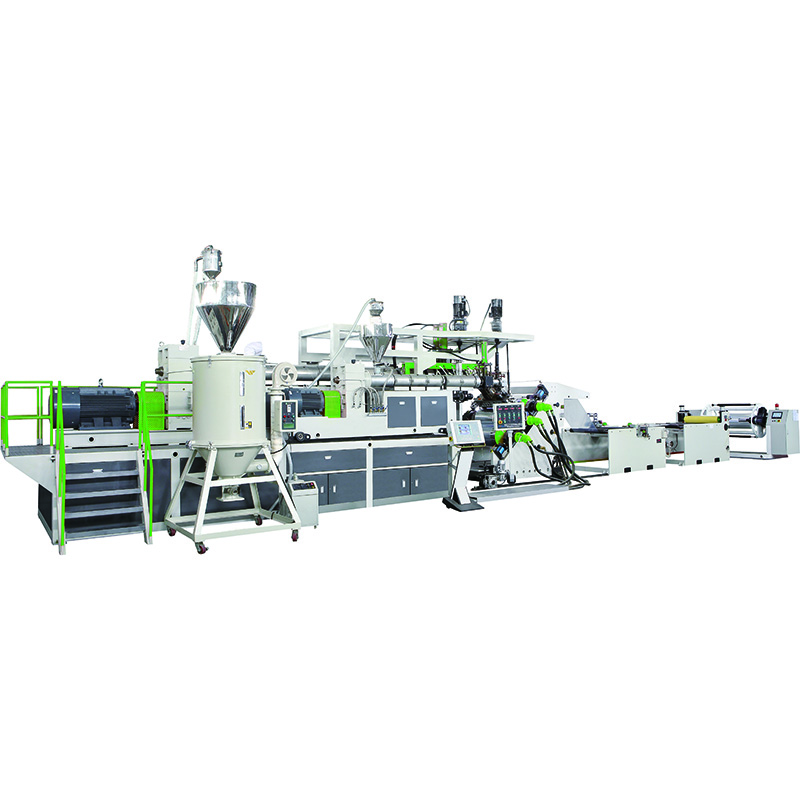

Working Principle:

The working principle of the PETG film extrusion production line is to melt PETG resin effectively using a high – performance extruder. After that, the melted resin is extruded through a precisely – designed die to form a continuous sheet. After extrusion, the film is quickly cooled and solidified by advanced cooling system to ensure smooth surface and high quality. After that, the film is pulled at a uniform speed with the help of the traction system, so as to avoid uneven stretching or warping. Finally, according to the precise specifications specified by customers, the cutting work is carried out, so that high-quality and high-performance PETG film products can be obtained.

Main Technical Features:

Extruder: The production line has advanced single – screw or twin – screw extruders. These extruders make sure that the PETG resin is fully plasticized and extruded evenly.his guarantees high production efficiency, consistent output, and a stable manufacturing process. The precise control over the extrusion process helps to minimize defects such as bubbles, uneven thickness, or surface imperfections.

Precision Die Design: High-precision die can accurately adjust the film thickness, thus improving the mechanical properties and appearance of the film. This fine control significantly enhances the overall performance of the film, making the production process more stable and smooth, and adapting to various application scenarios.

Temperature Control System of the Production Line: The temperature control system in the production line is very advanced. It can keep the extrusion temperature constant and at the best state. This system makes the PETG resin flow evenly in the extruder and keeps the material stable throughout the process. High – precision temperature control can reduce problems such as sagging, warping and poor adhesion, and improve the quality of the final products.

Cooling and Traction System: In line with the actual production needs, one can pick a water – cooled or an air – cooled cooling system. Quick cooling can effectively stop surface problems such as bubbles, stripes, and wrinkles. The traction system comes with precise rollers or belts that can steadily draw the film to prevent uneven stretching or the film from breaking, thus ensuring the film is output evenly.

High-Precision Cutting and Curling: The PETG film, which has been cut and hemmed with high precision, first goes through the processes of extrusion and cooling, and then enters the high-precision cutting system. This advanced cutting system can accurately cut the film into corresponding sizes according to the specific requirements of customers. After the cutting operation is completed, the film will be automatically wound into a compact coil for subsequent use and storage. The curling system can ensure that each roll has the same size and shape, which is convenient for handling, storage and further processing. This system has high precision, less waste of materials, and each volume meets the requirements of customers.

Automatic Control System: The automatic control system production line has advanced PLC control system, which is connected with the touch screen interface. This system can monitor and adjust the whole production process in real time. High degree of automation, without too much manual intervention, simple operation and high production efficiency. Moreover, the control system can record data and diagnose problems to ensure the quality and reliability in the production process.

Material Advantages:

Material Advantages:

High Transparency: High-transparency PETG film has outstanding transparency and optical clarity, and it is a well-deserved high-quality choice in high-end packaging, advertising and other application scenarios that require high visual effects. The high transparency of PETG can make the products clearly displayed, greatly enhance the visual experience of consumers, and make the products in the package get excellent display effect, thus attracting consumers’ attention better. Excellent heat resistance PETG material has strong heat resistance and is suitable for thin film application in high temperature environment.

Superior Heat Resistance: For example, food packaging should be able to withstand the heating of microwave oven and oven, and the protective film of electronic equipment should be able to resist heat. PETG does not deform at high temperature and has normal function. It is a reliable and durable material in these demanding applications.

Outstanding Impact Resistance and Durability: Excellent impact resistance and durability PETG film has good impact resistance and is durable, and it is not easy to break or crack under external force. It is a good material for packaging fragile or sensitive items, such as electronic products and medical equipment, which need impact protection. PETG is durable, the packaging can last longer, and the product safety is improved without old replacement.

Environmental Protection and Recyclability: PETG is a completely recyclable material, which meets the global requirements for environmental protection. It conforms to international environmental standards and is suitable for sustainable packaging. PETG can be recycled, can support circular economy, can be reused, and reduce waste and environmental impact. Enterprises choose PETG, which can achieve the goal of sustainable development and can also use high-performance packaging materials.

Excellent Processability: Excellent processability PETG film is easy to thermoform, print and do other post-processing.PETG can be used in different packaging forms, such as flip package, tray and blister package. This material has good processability and high printing quality, and is suitable for making product brands and labels. Whether it is simple packaging or complex design, PETG can meet the needs of customers.

Application Areas:

Packaging Industry: PETG film is widely used in the packaging industry, and is often used in the packaging of food, cosmetics, medicines and other consumer goods. It has high transparency, heat resistance and impact resistance, and becomes an ideal packaging material, especially suitable for packaging occasions that need both aesthetics and practicality.

Advertising Industry: PETG sheet can effectively extend the shelf life of products and provide long-term protection. In the advertising industry, it is widely used for outdoor and indoor display because of its high definition and high strength. For example, PETG films have important applications in logos, point-of-sale displays and promotional materials. It can also resist environmental influences such as ultraviolet rays, high temperature and humidity, and is very suitable for long-term use.

Medical industry: In the medical field, PETG film is often used to package medical equipment, diagnostic equipment and other medical products. It is shock-resistant and heat-resistant, can form a sterile barrier, and can ensure safety and protection during the storage and transportation of medical products. Moreover, PETG can be recycled, which meets the requirements of the medical industry for sustainable development. PETG film in electronic industry is widely used in protective packaging of screens, circuit boards and other precision equipment in electronic industry. It is heat-resistant and impact-resistant, and can protect electronic products from being damaged during transportation and handling.

PETG film is also useful in other industries. It can be used in places like home appliance packaging, consumer goods and art protection. It has many functions and strong adaptability, and it is a good choice for industries that want both functions and good looks.