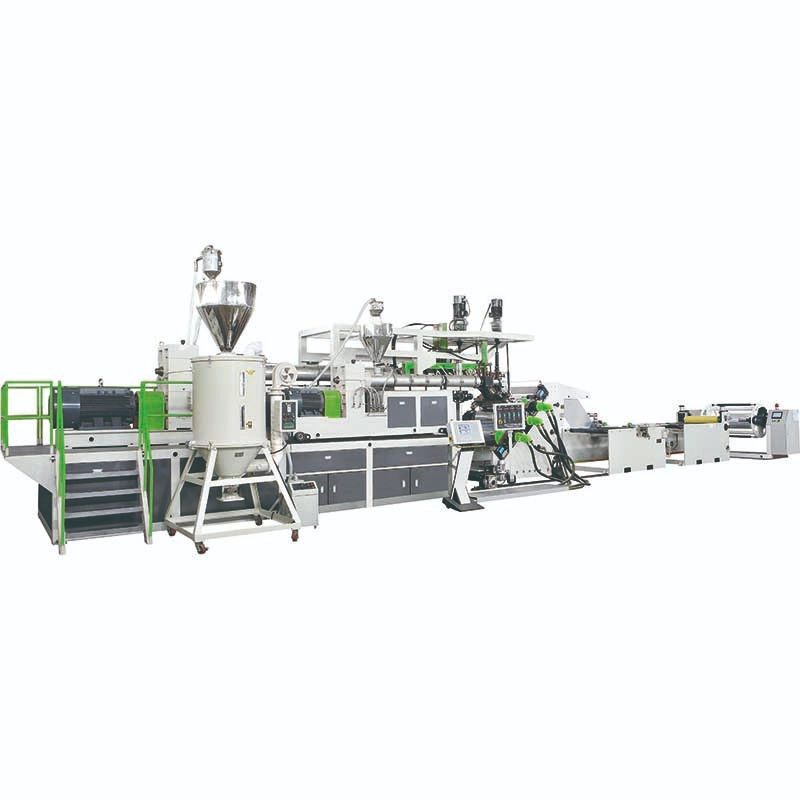

PS multi-layer sheet extrusion line is mainly used for the production of multi-layer composite environmental protection sheets, and the materials are mainly used for blister molding of various food containers and packaging, such as: trays, noodle bowls, lunch boxes, cake boxes, fruit bowls, etc. The equipment can effectively use the proportion of stone powder, which not only reduces the raw material cost of the plate, but also improves the degradability of the plate, and ensures the comprehensive physical properties and subsequent processability of the plate.

The machine adopts PLC control to realize automatic control of parameter setting, data calculation, feedback, alarm and other functions. The width of the sheet produced by this line is 1220-2100mm, the thickness range is 0.7-20mm, and the output is 50-600kg/h, and the output of different models is different.

PS multi-layer sheet extrusion line features:

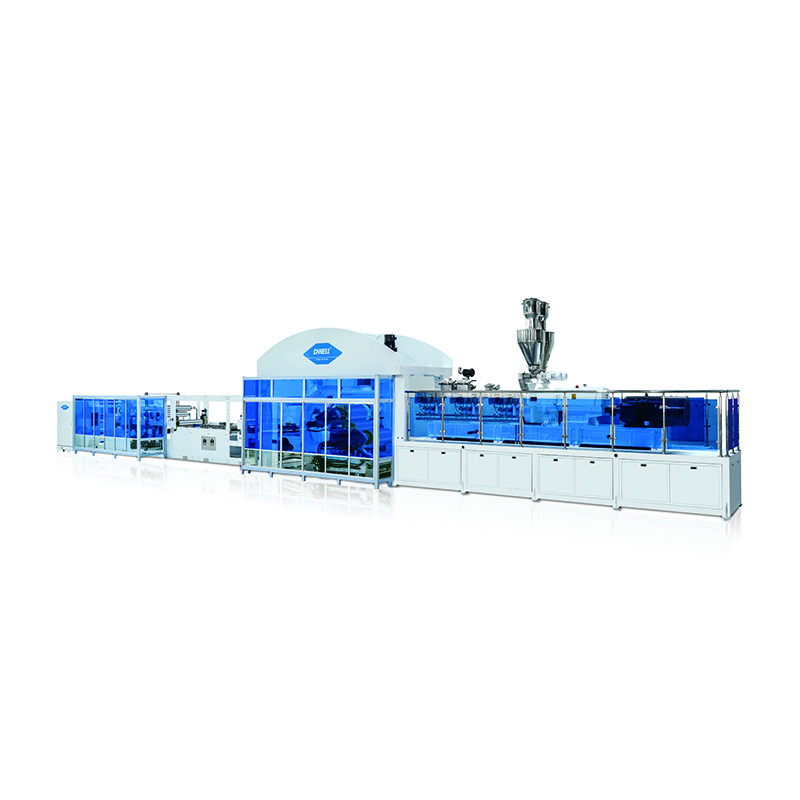

- The PP multi-layer sheet co-extrusion line can produces excellent barrier material with its advanced seven-layer to eleven-layer distribution technology. The vast majority of extrusion equipment factories are still making the five-layer distribution, while our co-extrusion technology is at the leading level in the industry. However, the energy consumption of our production line does not increase, but rather continues our long-standing advantages of high output in low energy consumption.

- The EVOH multi-layer film extrusion line adopts human-machine interface display, PLC control, which makes the production process become more intelligent. Highly intelligent machinery and equipment achieve high efficiency, high precision, high stability and high security and also can greatly reduces debugging and production downtime. The highly digitized system not can only saves costs, but also makes subsequent maintenance more convenient. Besides, this feature enhances production efficiency and reduces the likelihood of human error.

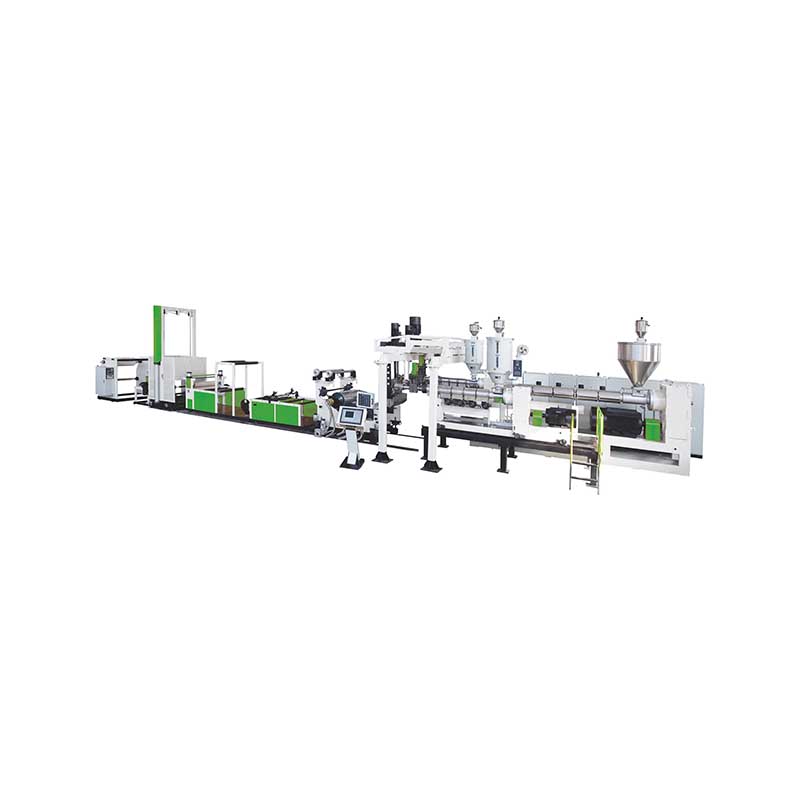

- In the structure of three rollers, we use the J type, which could make the sheet to be extruded with maximum cooling and shaping, and also could be adjusted to produce a wide range of thicknesses to meet different uses.

- We adopt servo motor in the winding part and it can be synchronized with the speed of the whole machine, which makes the winding process safer and simpler, and also reduces the waste of sheet caused by traditional winding methods.

- We have the most complete after-sales service system, all the production lines sold from our factory will have a turnkey project, which means the transaction will only be completed when the on-site commissioning is completed and there is no any problem. Our overseas technical team is all over the world, once the extrusion line is sold, customers can have lifelong after-sales, no matter what problems the machine has, customers can always find us to repair it for you.

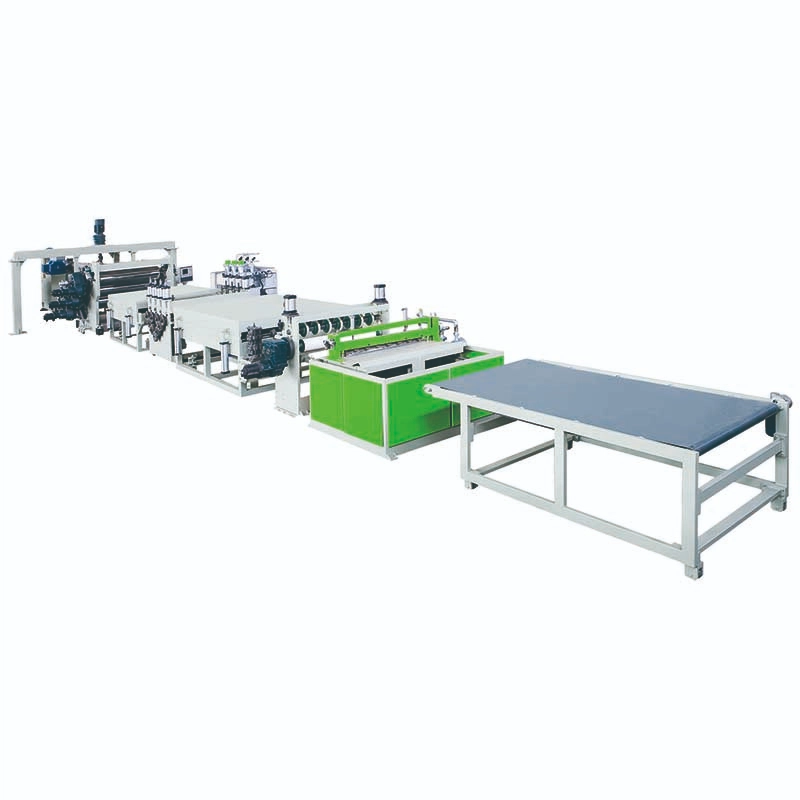

PS multi-layer sheet extrusion line Process Flows:

Extrusion line composition: Extruder — Screen changer — Melt pump — T-die — Calender — Thickness Scanner — Cooling Bracket — Cutting Knife — Haul-off — Winder.

To optimize production efficiency and film quality, our PS Multi-Layer Co-Extrusion Machine has been improved on a range of auxiliary equipment, including:

Feeding system: Our feeding system determines the number of hosts according to the number of product layers, ensuring that the various polymer materials are evenly distributed into the screw for melt mixing, and then filtered and distributed through the distributor, and the layer thickness and composition are controlled through the hanger-type flow channel.

Melt Pump: This component is used to stabilize the melt flow rate and ensure that the sheet can be output smoothly. Melt pumps help maintain optimal pressure and temperature, which is essential for producing high-quality sheets. Our equipment has reached a very fine level of temperature control, which is also an important manifestation of our professionalism.

Temperature control system: We use advanced temperature control technology, each layer can be processed at the ideal temperature, which can effectively prevent the thermal degradation of sensitive materials and ensure that the material properties are maintained, so that the final output sheets could keep the most perfect characteristics.

Cooling system: An efficient cooling system quickly cures the extruded sheets, maintaining it to the desired thickness and preventing warping or deformation. This process is essential to achieve the desired physical performance of the final product. The three rollers we use are connected to an independent temperature control system, which can control the temperature within the required range.

Die Technology: Our unique die design could makes layer shaped and distributed precisely. It guarantees that each layer adheres perfectly to the next, resulting in a sheet with excellent mechanical performance and visual quality.

Why choose PS plastic sheet?

- PS is a lightweight material with a low material density and which makes it be easy to handle and transport. At the same time, it has high rigidity and strength, suitable for making structural parts, and can be made into various shapes through various processing methods such as injection molding, extrusion, and thermoforming.

- It has good light transmittance and is suitable for making transparent products.

- It has some resistance to certain chemicals, but is sensitive to solvents and high temperature environments. After molding, the surface is smooth, which is suitable for high-demand appearance products.

- PS material is easy to color and print, and can be easily colored and printed to meet different design needs.

After-sales service content:

We always insist on providing comprehensive after-sales support to ensure that our customers get the most out of their investment. Our services include:

1.Installation & Commissioning: Our experienced technicians will help install and commission the machine, ensuring it is running at peak performance from day one.

2.Training Programs: We offer training courses for your operators that cover machine operation, maintenance, and troubleshooting to maximize efficiency and minimize downtime.

3.Technical Support: Our dedicated support team is located overseas and is always available to help you with any technical issues or queries that may arise during your operation. We provide timely assistance to ensure that your production runs smoothly. The equipment has been sold and can enjoy a lifetime after-sales service

Contact us

For more information about the PS multi-layer co-extruder or to discuss your specific needs, please contact our sales team. We are committed to providing you with the best solution to meet your production goals.

Single-Screw-Dryer-Free-Vented-PET-SheetPlate-Extrusion-Line.jpg)