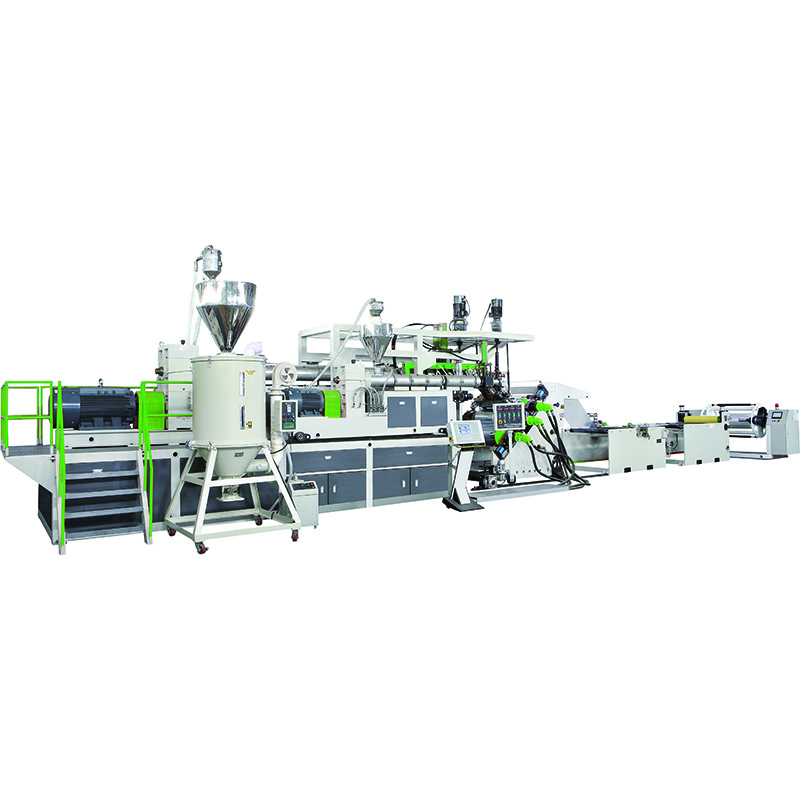

Key Features of the PC Optical Sheet Production Line:

- Upgraded Screw Design: At the heart of our line is an upgraded screw design that ensures enhanced material flow during the extrusion process, allowing it to be more fully agitated and mixed in the screw barrel. This improved screw construction helps to obtain a more homogeneous sheet, reducing defects and optimizing the quality of the final sheet. The design ensures stable output and consistent thickness, which is essential for the production of high-quality optical sheets for sensitive applications.

- Advanced servo motor imported from Germany: The extrusion line is equipped with advanced servo motor imported from Germany to ensure speed synchronization, which is also a sign of our precision and efficiency. These motors have excellent control over speed, torque, and positioning, making them essential for the precise operation of the extrusion process. They contribute to the high responsiveness of the system, enabling precise adjustments and ensuring the production of PC optical sheets with minimal deviations. The use of high-end servo motors reduces energy consumption and minimizes mechanical wear, which can also extend the life of the entire system.

- CNC Machining Key Components: Every key component of the PC optical sheet production line is precision machined using CNC (Computer Numerical Control) technology. This guarantees high accuracy and consistency in the performance of the equipment. The use of CNC machining ensures that components such as rollers, screws, and dies are manufactured to precise specifications, minimizing the risk of mechanical failure and ensuring the smooth running of the entire production line. This also avoids unnecessary errors that can be caused by manual operation.

- Fully Automatic Constant Tension Control Winder: This extrusion line is equipped with a fully automatic constant tension winder, which is a complex function that plays a vital role in ensuring the smooth winding of the produced optical sheets. The system automatically adjusts the tension to prevent wrinkles or stretching during the winding process, ensuring that the finished sheet retains its quality and integrity. The highly automated automatic winder minimizes human intervention, increases the efficiency of the production process, and reduces potential errors.

- State-of-the-art domestic manufacturing: The entire production line, including all its components and systems, is assembled and tested in accordance with international standards, while maintaining an extremely high level of domestic craftsmanship. With a focus on precision, durability and performance, the line is at the leading level in China, delivering best-in-class results that are comparable to international standards.

Properties of PC Optical Sheets:

PC optical sheets are known for their exceptional clarity, high impact resistance, and superior light transmission properties. These qualities make them being ideal for a wide range of optical and industrial applications.

- High Optical Clarity: PC optical sheets provide high transparency and excellent optical clarity, making them ideal for use in applications such as light guides, lenses, and optical displays where visual performance is critical.

- Superior Impact Resistance: Polycarbonate is a highly durable material with excellent impact resistance, which is one of the reasons PC optical sheets are commonly used in safety applications, signage, and protective covers. The high strength of PC optical sheets ensures that they can withstand significant impact forces without breaking or shattering, making them more reliable than acrylic or glass alternatives in many applications.

- Excellent Light Transmission: PC optical sheets exhibit excellent light transmission properties, making them ideal for use in applications where light diffusion is important. These include backlighting for displays, light diffusion panels, and other optical devices that require precise control over light distribution.

- Weather Resistance: PC optical sheets also offer strong resistance to UV radiation, weathering, and other environmental factors, which ensures their long-term performance in outdoor applications such as signage, lighting fixtures, and protective panels.

- Thermal Stability: With a high glass transition temperature, PC optical sheets maintain stability even in higher temperatures, making them suitable for use in heat-sensitive environments and for long-term outdoor exposure.

Applications of PC Optical Sheets:

Due to their remarkable optical and mechanical properties, PC optical sheets are widely used in several industries, including:

- Display Industry: PC optical sheets are often used in the display industry, particularly for LCD backlighting and light guides. Their high light transmission and ability to diffuse light evenly make them perfect for enhancing the brightness and uniformity of display screens, from televisions to smartphones.

- Lighting Industry: In the lighting industry, PC optical sheets are used in LED panels and lighting diffusers. Their high impact resistance and excellent light transmission properties ensure that the sheets can protect light sources while also providing an even and consistent light output.

- Optical Lenses and Covers: PC optical sheets are used for making optical lenses, protective covers, and lenses for cameras or optical instruments, thanks to their high clarity and durability.

- Signage and Safety Applications: The impact-resistant properties of PC optical sheets make them perfect for signage, traffic light covers, and safety windows, where visibility and durability are crucial.

- Automotive Industry: PC optical sheets are increasingly used in automotive lighting and headlamps, as their ability to withstand extreme temperatures and impacts makes them a preferred choice for automotive manufacturers.

After-Sales Service

We take pride in providing exceptional after-sales support to our clients. Our commitment to customer satisfaction doesn’t end with the purchase of the extrusion line; it continues throughout the life cycle of the equipment. We offer:

- Comprehensive Installation & Commissioning Services: Our team of highly skilled technicians will assist with the installation and commissioning of the PC optical sheet extrusion line at your facility. We ensure that the equipment is set up properly and runs at peak performance from the start.

- Ongoing Technical Support: Our experienced engineers are available to provide troubleshooting, maintenance, and repair support at any time. We offer remote support for immediate issues and on-site service when necessary.

- Training for Operators: To ensure that your team can operate the equipment efficiently and safely, we offer comprehensive training sessions. These cover the operation, maintenance, and troubleshooting of the production line, helping to maximize productivity and reduce the risk of operational errors.

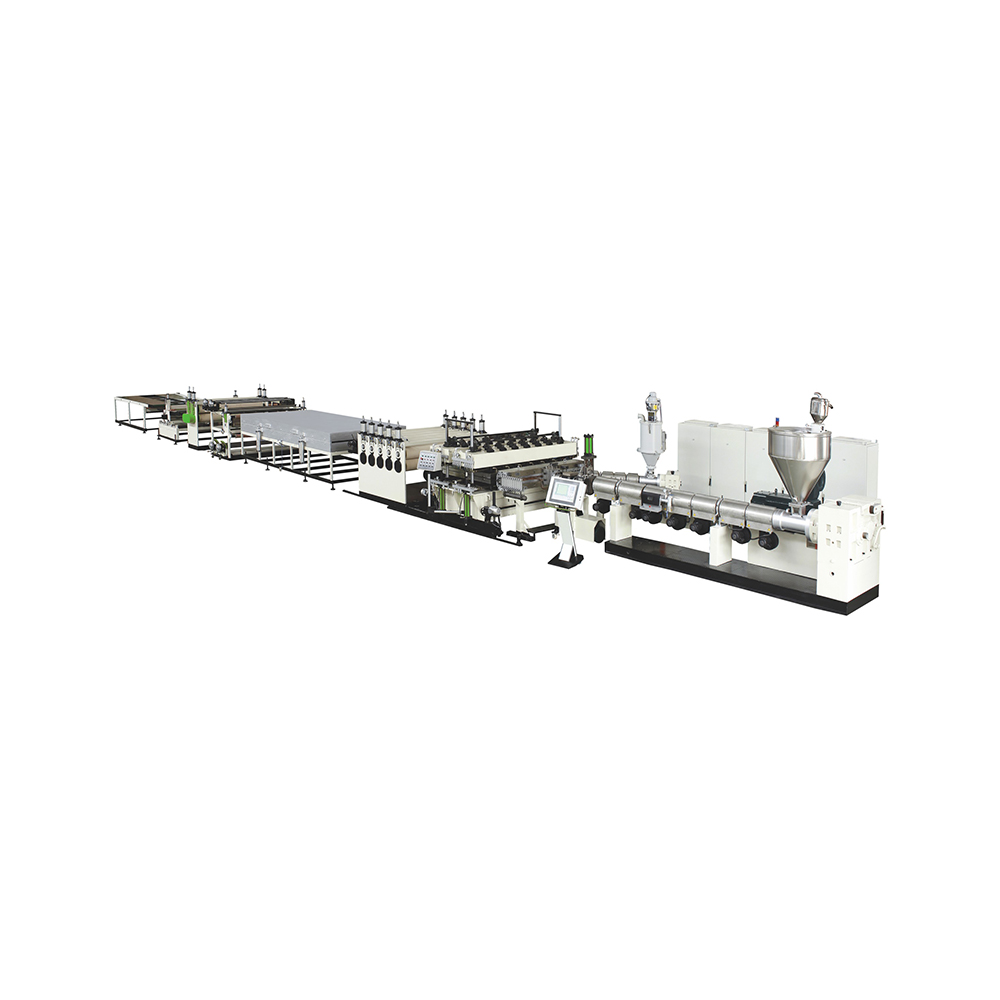

TPU-Casting-Film-Production-LINE.png)

PC-Optic-Sheet-Extrusion-Line.jpg)