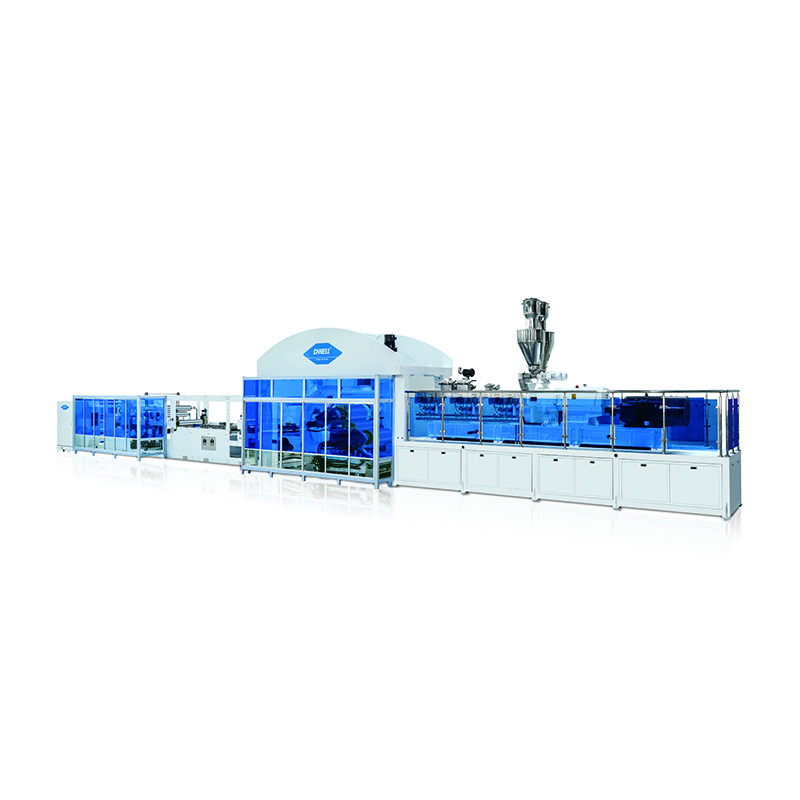

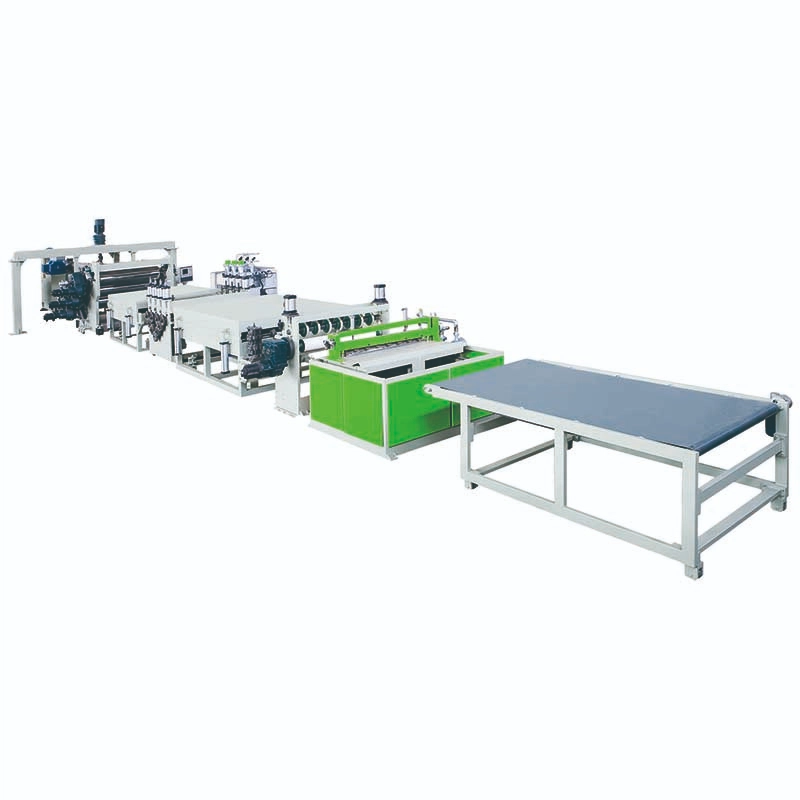

1.Product Introduction

PVC Free Foam Sheet Extrusion Lines are designed to produce PVC foam sheets without an outer skin layer. Known as “free foam” sheets, these products have a slightly textured surface, are porous and are ideal for applications that require painting, printing or lamination. Made from PVC resin combined with a foaming agent, these sheets are a lightweight, durable alternative to wood, MDF and other traditional materials. They are also waterproof, flame retardant, termite and mildew resistant, making them ideal for indoor and outdoor applications in a wide range of industries.

2.Market Overview

The demand for PVC free foam board becomes more and more cheaper, because of lightweight and using widely. It’s popular in architecture, interior design and advertising industry. They like using PVC free foam board on covering board, signs and furniture manufacture. These products are very welcome in North America, Europe and Asian-Pacific region. Due to the rapidly development of industrialization and urbanization, Demand is also increasing in emerging economies such as South America, the Middle East and Africa. In future few years, the global PVC free foam board market is predicted to grow at a CAGR about 9%-10%. It reflects that people preference of cost-effective and sustainable building materials is increasing.

3.Applications of PVC Free Foaming Boards

Architecture and Interior Design: These sheets are used for wall panels, partitions, and ceilings. The textured surface allows for easy painting and lamination, making them suitable for interior decoration.

Furniture and Cabinets: PVC free foam sheets are often used for cabinets, shelving, and other furniture components because they are lightweight and resistant to moisture and insects.

Advertising and Displays: These sheets are often used for signs, advertising displays, and exhibition materials because of their smooth, customizable surface. They are easily printed, painted, and cut to size.

Packaging: Free foam sheets are sometimes used in specialized packaging applications because they are lightweight and durable.

4.Competitive Analysis

The PVC foamless extrusion equipment market is highly competitive, with both well-known global players and a range of regional manufacturers. Major companies in this field include Battenfeld-Cincinnati and KraussMaffei, as well as several strong manufacturers from China and India that offer competitively priced equipment with high adaptability to local markets. Key factors affecting competition include:

Technological innovation: Companies that adopt advanced automation, energy saving and digital monitoring features are better able to attract customers. High-output machines that are easy to maintain are particularly attractive.

Cost efficiency: Since PVC foamless boards are often favored for their affordability, manufacturers that offer efficient, cost-effective production lines can meet the expectations of customers in developed and emerging markets.

Customization and after-sales service: Companies that provide customized solutions for different board specifications and provide extensive after-sales support (including training, maintenance and spare parts) will gain higher customer loyalty.

Environmental compliance: As environmental regulations tighten around the world, equipment that supports low-emission, sustainable production methods is increasingly valued, especially in the European Union, North America and parts of Asia.

5.Market Trends and Customer Preferences

Increasing of sustainable material : with the advocate of environmental protection, the demand of PVC-free foam board production is also increasing.

The preference of light, multifunction: architecture, furniture, and advertising industry become more and more preferable to the materials that are easy to transport, install, and customize. It is useful for the PVC-free foam board market.

Demand for High-Quality Surface Finishes: Customers in the furniture and advertising industries seek sheets that can be printed or painted with smooth, high quality, which is driving interest in foam-free sheets with finely textured surfaces.

6.Opportunities and Future Growth Potential

The PVC non-foamed board extrusion line has a bright future, with strong growth potential in both mature and emerging markets. The Asia-Pacific region shows considerable demand due to the continued expansion of the construction and advertising industries, while North America and Europe continue to seek environmentally friendly, cost-effective building materials. By focusing on product quality, innovation and environmental compliance, manufacturers can take advantage of the growing demand for lightweight, sustainable materials and capture a significant share of this expanding market.