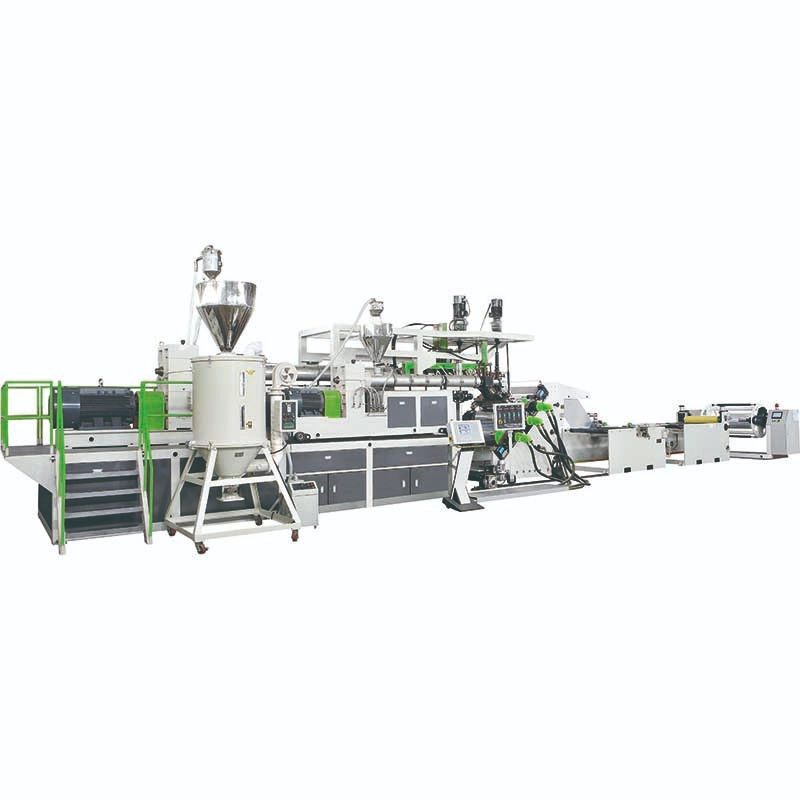

- Working Principle

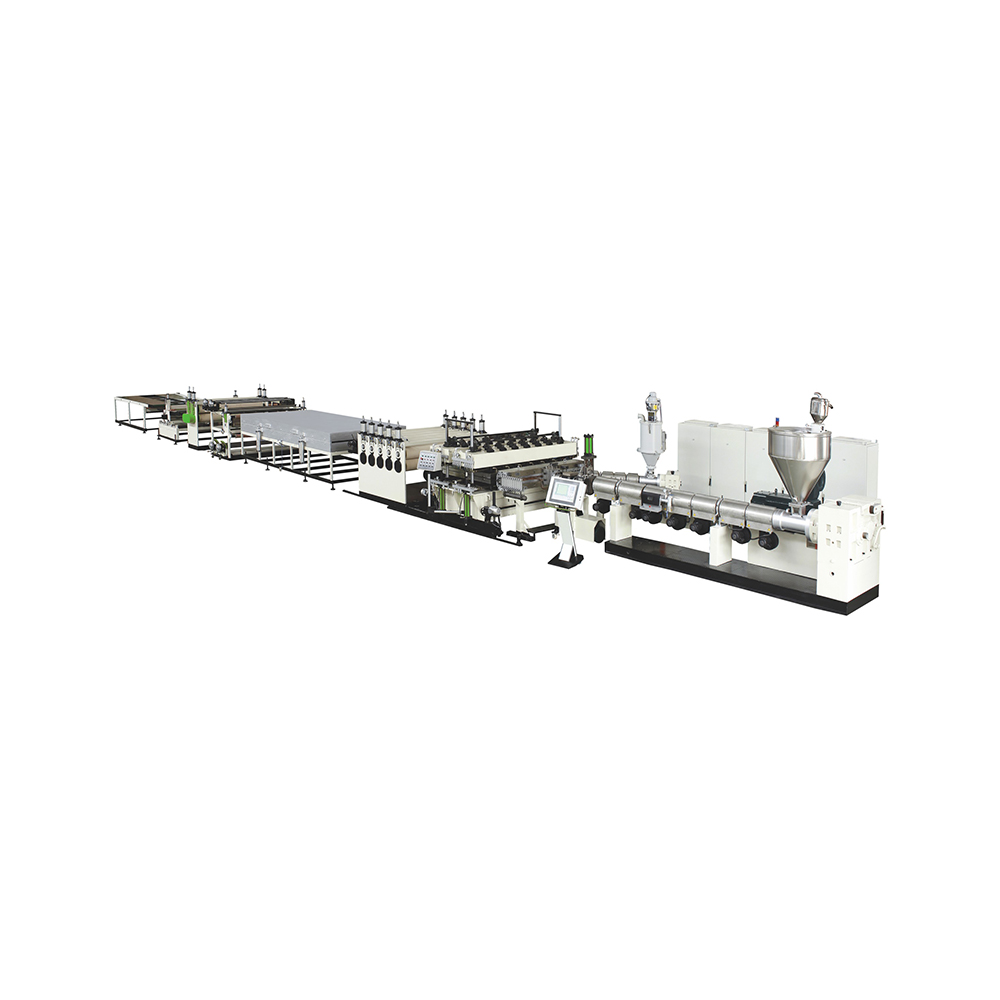

Working principle of CPET plastic sheet extrusion production line: raw materials are treated first, CPET plastic particles are fed and dried, then enter the extruder, and the raw materials are melted and plasticized by barrel heating and screw action. The melt is extruded into a sheet through a die, the thickness of which can be adjusted, then cooled and shaped, then drawn and stretched to improve the mechanical properties, and finally wound and cut as required.

DWELL CPET plastic sheet extrusion line combines advanced technology and innovative design, and is committed to providing efficient, energy-saving and environmentally friendly production solutions. Its unique material advantages complement the equipment advantages, ensuring the excellent performance and wide application of products in food packaging and other industries.

- Excellent material advantages

Stay CPET sheets use high-quality CPET materials, which have many outstanding advantages and are widely used in the packaging industry. High temperature resistance: CPET tablets can withstand the temperature of more than 220℃, suitable for microwave heating and frozen food packaging, and can maintain structural stability in high and low temperature environment, to meet the strict requirements of modern food packaging industry for heat resistance and temperature control performance.

Excellent impact resistance: CPET materials have excellent impact resistance, even under drastic temperature changes, they can remain stable, not easy to break or deform, ensuring that food packaging is intact during transportation and storage.

Food safety assurance: CPET is a non-toxic material that meets international food safety standards. It is widely used in the field of food packaging to effectively protect food hygiene and safety and enhance consumer trust. Environmental protection and recyclability: CPET is a recyclable and environmentally friendly material that meets the requirements of modern society for sustainable development.

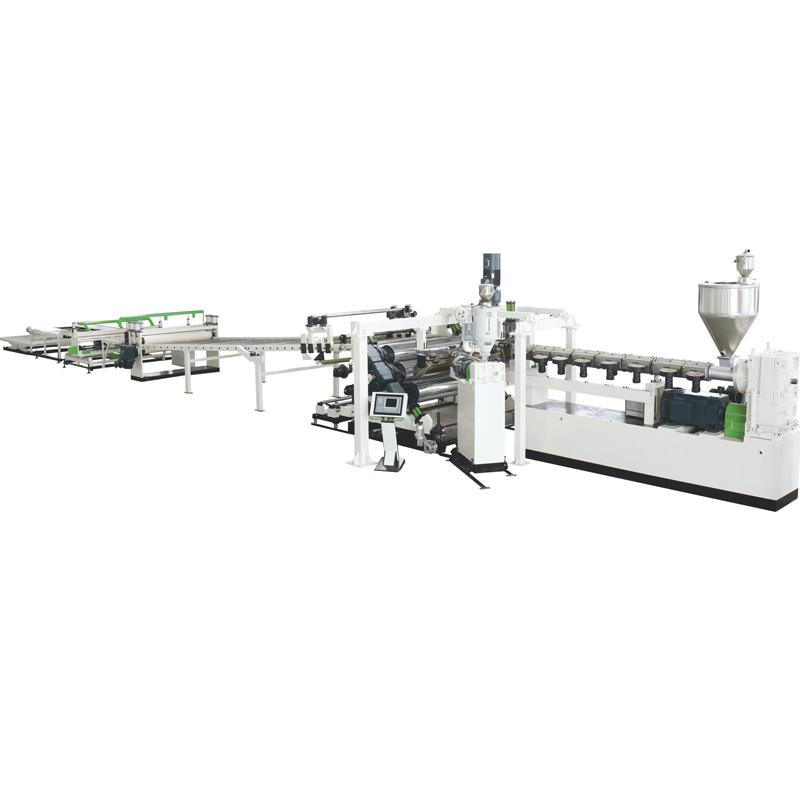

- Advantages of high-efficiency and energy-saving equipment

DWELL CPET Plate extrusion production line combines modern technology with innovative design, while maintaining high quality standards, ensuring the highest efficiency in the production process, reducing energy consumption.

- High degree of automation and intelligent control: the device is equipped with an advanced PLC automation control system. Operators can monitor and adjust the whole production process in real time through the touch screen interface, greatly reducing manual intervention and improving the accuracy and safety of the production line operation. At the same time, the system supports remote diagnosis and maintenance to ensure the efficient operation of the equipment and reduce the equipment downtime and maintenance costs.

- Precision production, high stability: high efficient double screw extruder combined with precision mold design ensures the uniform heating and plasticizing of the material in the extrusion process, the product thickness and width accuracy are high, and the plate quality is stable. This precise control enables production lines to steadily conduct mass production and production.

3, Efficient winding system and subsequent processing convenience

Intelligent tension control and automatic winding: The automatic winding system is equipped with intelligent tension control to ensure that the sheet is tight and neat during the winding process, avoiding loose or stretched deformation of the coil. By adjusting the tension, the winding system can adapt to different production needs, ensure the stability of the sheet, and facilitate subsequent transportation, storage and processing.

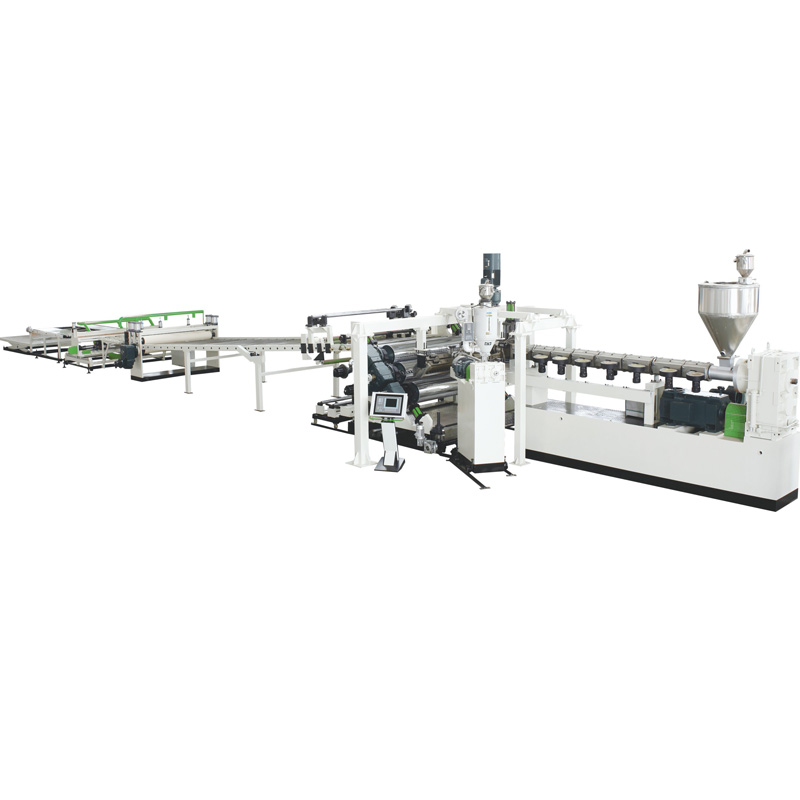

- Comprehensive benefits: high efficiency, low cost, green production

DWELL CPET sheet extrusion production line not only improves production efficiency and product quality, but also helps enterprises reduce production costs, reduce energy consumption, and achieve environmental protection goals. Highly automated control system, meticulous production process and energy-saving design ensure the production of high-quality products and minimize the company’s operating costs. In addition, the selection of environmentally friendly and recyclable materials will enable the company to conform to the global trend of green packaging and promote sustainable development.

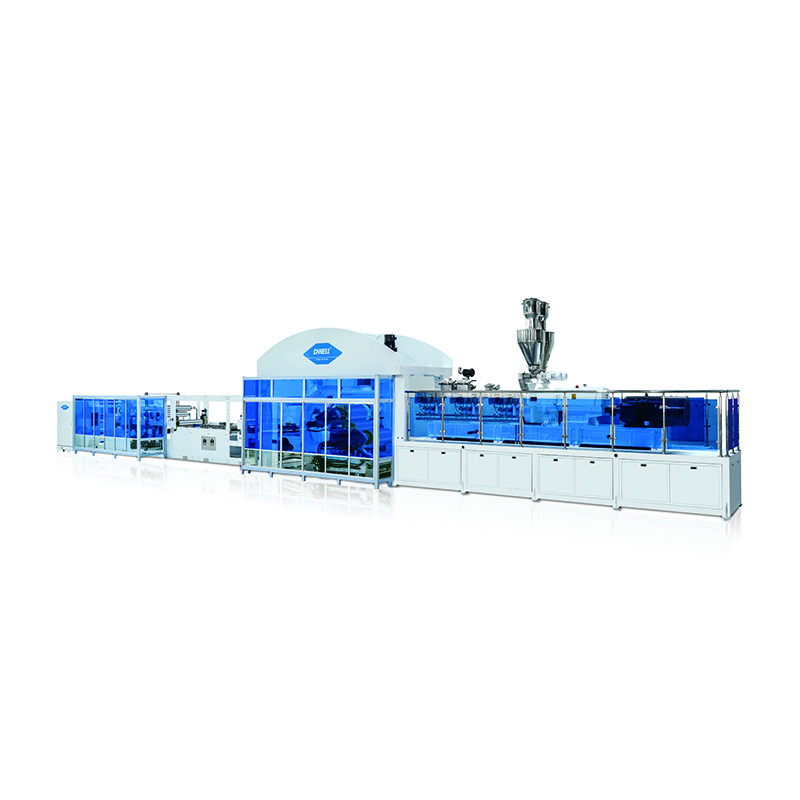

Summary

DWELL CPET plastic sheet extrusion production line has become an ideal production equipment for food packaging and other related industries with its advantages in material selection, equipment design, production efficiency, energy saving and environmental protection, and flexible adaptability. Whether facing growing market demand or increasingly stringent environmental regulations, DWELL production line can provide enterprises with efficient, stable, economical and sustainable production solutions, driving enterprises to stand out in the fierce market competition.