Produce:

EVA is a kind of thermosetting and adhesive film, which is used in the middle of laminated glass. Due to the advantages of EVA film in adhesion, durability and optical characteristics, it is widely used in current components and various optical products.

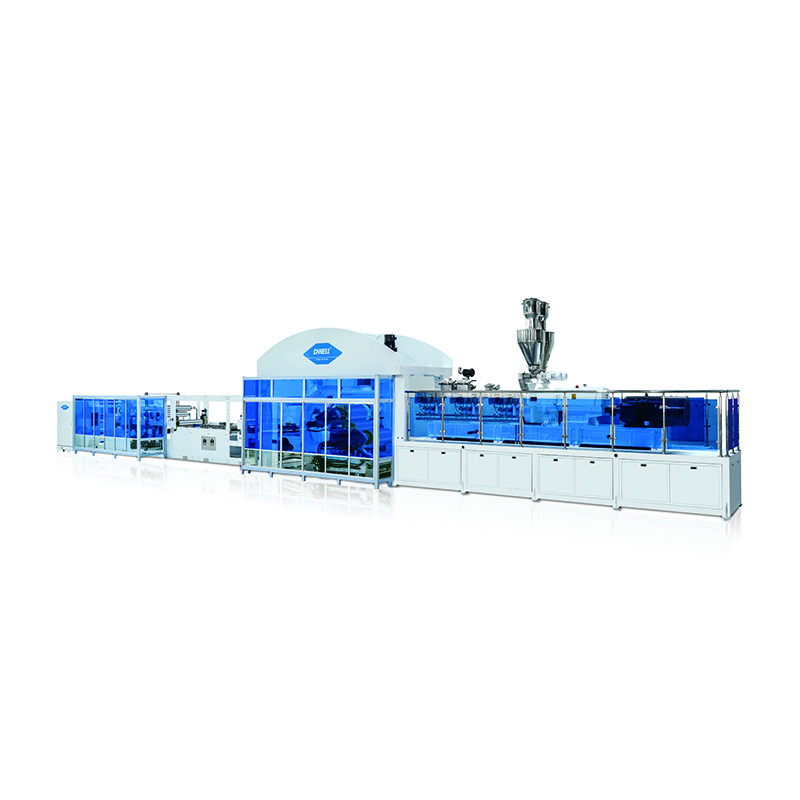

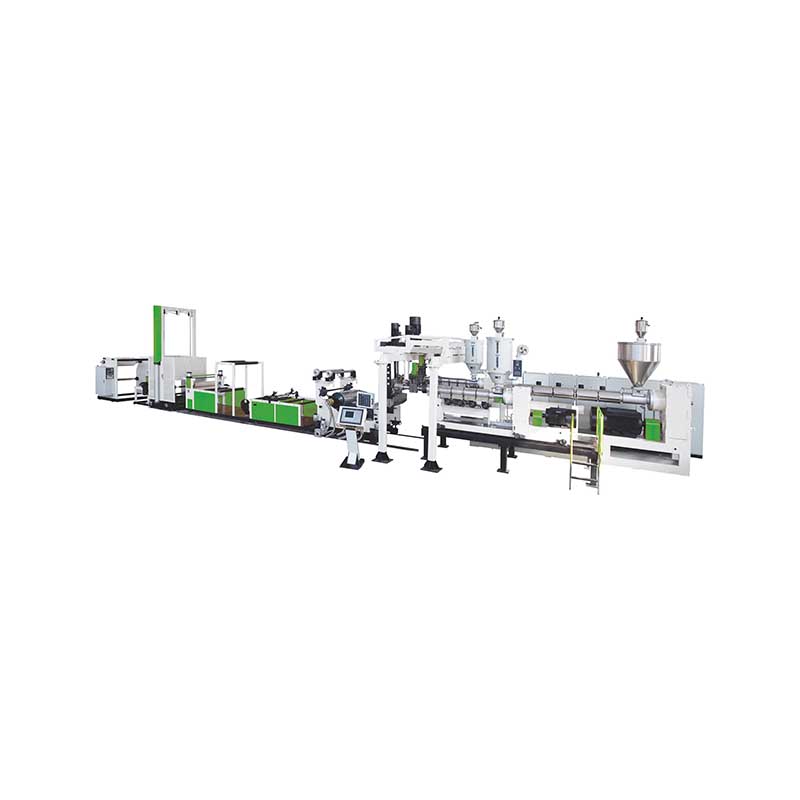

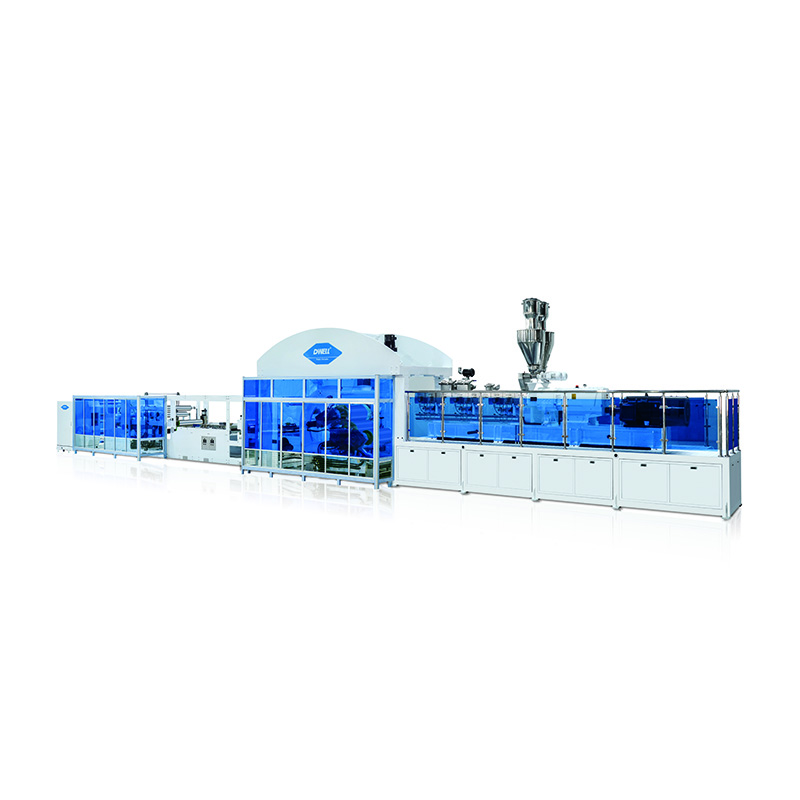

EVA (ethyl-vinyl acetate) films are produced using a variety of methods, including packaging, solar panels, and construction materials, using the premium eva film extrusion line. EVA pellets are melted before being forced through a die to form a film of the desired thickness and width. The preparation of raw materials is the first step in the production process. The feed screw feeds the EVA pellets into the hopper before conveying them to the extruder. The pellets are melted and homogenized by the extruder using heat and pressure. After being melted, the molten EVA is then passed through a die to create a film that has the desired thickness and width. The extruded film is then chilled and used to solidify the chill rolls. For processing or packaging, the cooled film is then wound onto rolls.

On the market, there are a lot of different kinds of eva film extrusion lines, each with its own benefits and drawbacks. Some are made specifically for large-scale production, while others are made for laboratory or small-scale use. The manufacturer’s specific needs and requirements will determine the line of extrusion for EVA film.

Advantages of EVA:

The EVA material is lightweight, which makes it a great advantage in the packaging and transportation fields. The EVA material is less dense, so the product weight is very light, which can effectively reduce the transportation costs and reduce the burden on the environment.

In addition, EVA material also has good elasticity and softness, so that it can absorb and disperse the external impact force, providing superior protection effect.

The EVA material has outstanding water resistance and chemical corrosion resistance. This feature makes EVA materials equally good in outdoor and high humidity environments, providing reliable protection both for waterproof equipment and for a variety of protective clothing.

The EVA material also has an advantage in environmental protection. EVA material itself is non-toxic and harmless, easy to recycle after waste, in line with the requirements of modern society for environmental protection and sustainable development.

Advantages of EVA film:

1,EVA film with high transparency and high adhesion can be applied to a variety of interfaces, including glass, metal, as well as plastics,such as PET.

2,Good durability can resist high temperature, moisture and ultraviolet light.

3,Easy storage, stored at room temperature, EVA adhesion is not affected by humidity and absorbent film.

4,Compared to PVB has a stronger sound insulation effect, especially the high frequency of sound effects.

5,Low melting point, easy to flow, can be suitable to all kinds of glass lamination process, such as embossed glass, tempered glass, bent glass, etc.

Application of China eva film extrusion line products:

Application for products from China’s Extrusion Film Extrusion line The products are widely used in safety board laminated glass, curved laminated glass, craft laminated glass, bulletproof glass, color-changing laminated glass, conductive smart glass, solar cells, etc.

The products are frequently used in: medical surgical gowns, baby diaper films, women’s sanitary napkin bottom films, adult diaper films, pet pad films, disposable bed sheets, etc.

Frequently needed items include umbrellas, raincoats, suit jackets, tablecloths, shower caps, shower curtains, aprons, chair covers, etc. supplies for packaging materials like computer and electrical appliances, flexible cosmetic bags, gift bags, document bags, etc.

FAQS:

What kind of machine does DWELL produce?

Our main products are plastic extruder, extrusion series of line:PET single-layer co-extrusion sheet extrusion line;PP,PS single-layer/multi-layer co-extrusion line;ABS,HIPS automobile panel,refrigerator plate and bags plate extrusion line;PC,PMMA optic sheet extrusion line;PMMA,PC,GPPS plate extrusion line;PP,PE,PVC thick plate extrusion line;PP,PE,PC hollow cross section plate extrusion line;PP,EVA,EVOH,PP five-layer/seven-layer co-extrusion line,PC,PET,PVC corrugated plate extrusion line,TPU Casting Film Production Line,EVA/POE/PVB/SGP Film Extrusion line,etc.It also includes the sales and service of kinds of single-screw,double-screw,cylinder,plasticsheet/plate-die,screen changers,distributor,mirror surface roller and flower pattern roller.

Is DWELL Machinery a Manufacturer?

Yes,DWELL is a manufacturer,We own 2 manufacturing bases in Dongguan,Chuzhou China,It covers an area of 100000 square meters and has 200 technology management employees,a professional plastic extrusion and thermoforming&blister machinery manufacturer,including of R&D,designing,processing,sales and services.

How long is the delivery date?

Usually it takes about 1 – 4 months depends on different machinery upon receipt of order advance payment.

Can Dwell provide professional pre-sale service?

Yes,Dwell sale teams will provide specification according to customer’s requirements,meanwhile we can give the technical support to customers. If you need,please contact us!

Can DWELL provide after sale service?

Yes, we support our business partners by after sale service. We provide one year of free after-sales repair service,

What about the payment way?

A:By TT, L/C at sight or Alibaba trade assurance. 30% down payment should be paid after contract is valid, 70% balance should be paid before shipment.

Single-Screw-Dryer-Free-Vented-PET-SheetPlate-Extrusion-Line.jpg)