(一) Production processes

- Raw material preparation

Dwell selects high quality GPPS pellets as raw material, so that the flow and molding properties will be very good to ensure smooth extrusion process. In terms of storage, Dwell strictly adheres to a dry environment, as GPPS pellets are hygroscopic and moisture absorption may result in defects such as air bubbles during extrusion, which may affect the quality of the sheet. In addition, to ensure uniformity of extrusion, pellets are screened to remove possible lumps or impurities.

- Extrusion process

After the raw material enters the main machine, the screw in the extruder will rotate to push the raw material forward, and at the same time, the barrel will be heated to melt and plasticize the GPPS rapidly. The temperature control of the barrel is divided into several zones, from the feeding section to the head, the temperature gradually increases, generally between 180 – 230 ℃, and the temperature of each zone can be accurately regulated, to ensure that the GPPS is uniformly plasticized under the optimal temperature conditions, to avoid local overheating leading to decomposition of the material. During the extrusion process, the screw speed can be flexibly adjusted within a certain range according to the production demand, usually 10 – 60rpm, to adapt to the production of different thickness and width of the sheet.

- Cooling and Calibration

The extruded GPPS sheet will enter the cooling zone. The initial cooling is done by air cooling to harden the surface of the sheet and prevent deformation; then it enters the water cooling zone, where the circulating water is used to further reduce the internal temperature of the sheet and ensure uniform cooling of the product as a whole. The cooling speed is precisely adjusted by the control system to balance production efficiency and product quality. The calibration unit is equipped with high-precision rollers, the surface of which has been specially treated with high hardness and low roughness to exert uniform pressure on the molded sheet to ensure that the product reaches the precise dimensions and is produced strictly in accordance with the customer’s requirements.

- Cutting and finishing

Cutting equipment will be selected according to product specifications and production requirements. For regular sized sheets, high speed circular saws are mostly used, with saw blade speed up to 3000 – 5000rpm and cutting accuracy up to ±0.5mm, which can realize efficient and fast cutting. For plates with higher precision requirements or complex shapes, such as shaped plates used for high-end decoration, laser cutting machines are used, whose cutting precision can be controlled within ±0.1mm, and can cut out a variety of exquisite patterns and shapes. The edges of the cut sheets are finished to different degrees according to the application requirements. For packaging products, the edge of a simple chamfering treatment to prevent scratches; for architectural decorative panels, will be fine polishing and sanding, so that the surface is as smooth as a mirror, to enhance the aesthetics of the product.

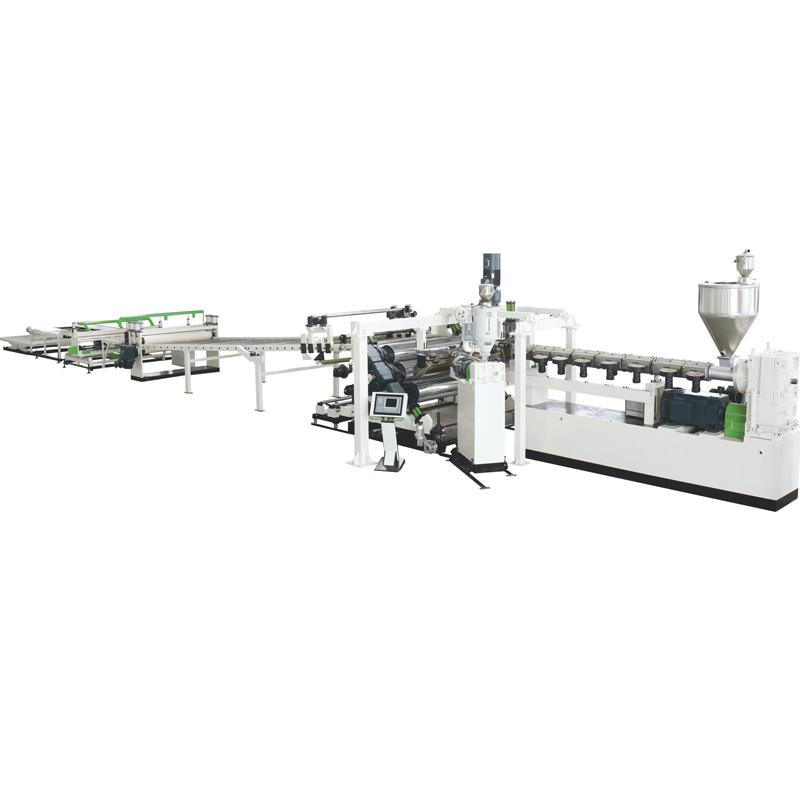

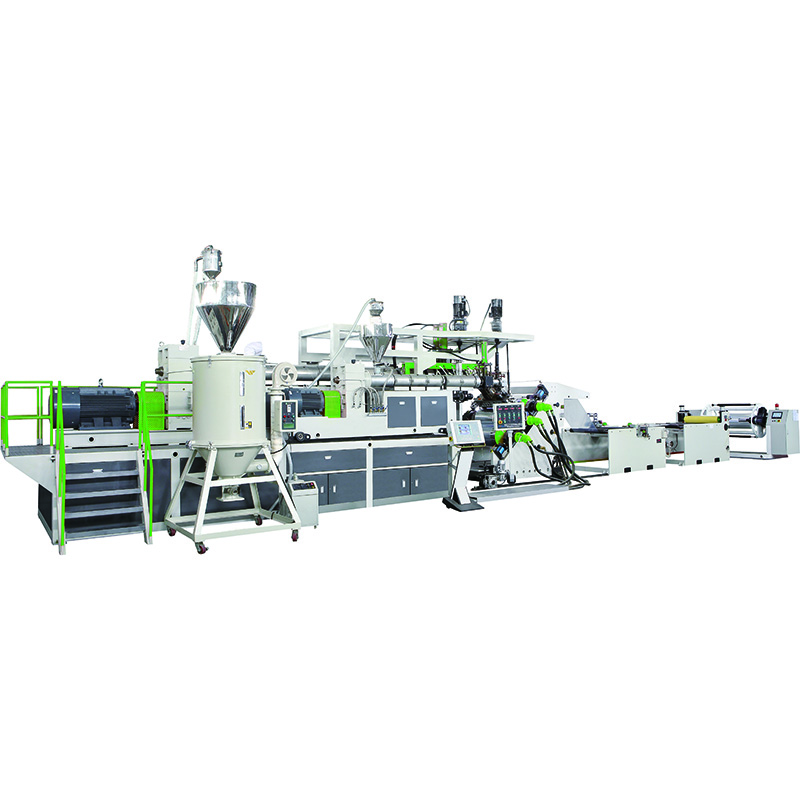

(二) Equipment Composition

- Extruder

Extruder is the key part of the production line, which is composed of several important parts. Its feeding system adopts vacuum loading device, which can avoid the particles inhaling air in the conveying process and ensure the stability and uniformity of feeding. The barrel is made of high-quality alloy steel, which has good resistance to high temperature and abrasion, and the inner wall is treated with special nitriding treatment, which further improves its hardness and abrasion resistance, and prolongs the service life of the barrel. The screw is made of high-strength nitrided steel, with surface hardness up to HV900 – 1000, and the screw’s L/D ratio is optimized, generally between 25 – 30, to ensure that the material has enough residence time for plasticizing. The heating system adopts zoned ceramic heating ring, which can heat up quickly and control the temperature accurately; the cooling system is spiral water-cooling device with high cooling efficiency, which can effectively take away the excess heat of the barrel.

- Die head

The die head is the key component that determines the shape and dimensional accuracy of the product. The hanger type runner design can make the molten GPPS evenly distributed in the die head to ensure the uniform thickness of the sheet. The internal runner surface of the die head is finely polished, with a roughness of Ra0.8 or less, which reduces the resistance to material flow and prevents material retention and decomposition. The lip gap of the die head can be precisely adjusted from 0.5 – 10mm. With the high precision adjustment device, the thickness of the sheet can be quickly adjusted according to the production demand and remain stable during the production process.

- Cooling calibration system

The cooling calibration system consists of cooling frame, cooling roller, calibration roller and water circulation system. The cooling frame is made of high-strength aluminum alloy, which has good heat dissipation performance and structural stability. The surface of cooling roller adopts chrome plating treatment, the thickness of chrome plating layer is uniform, high hardness, corrosion resistance, which can effectively improve the service life and heat transfer performance of the roller. The calibration roller is supported by high-precision ball bearings and rotates flexibly, which ensures uniform and stable pressure on the plates. The water circulation system is equipped with energy-efficient water pumps and cooling towers, which can provide stable circulating water flow and temperature to ensure the consistency of cooling effect.

- Cutting equipment

There are various types of cutting equipment to meet different production needs. Cutting equipments are equipped with advanced automation control system, which can realize automatic fixed-length cutting, automatic counting and other functions to improve production efficiency and product precision. Meanwhile, in order to ensure the safety of the operators, the cutting equipment is also equipped with perfect safety protection devices, such as protective doors, emergency stop buttons and so on.

(三)Product Classification

1.Ordinary GPPS sheet

(1)Packaging Material Application: Ordinary GPPS sheet is widely used within the packaging industry. Due to its excellent transparency and resistance to moisture and chemicals, it is commonly used to make food containers, such as disposable cups, plates and food trays, and can also be used for blister packaging of consumer products.

(2)Architectural and Decorative Material Applications: In the architectural field, GPPS sheets are used as interior decorative panels. They can be printed in a variety of patterns and colors to simulate the appearance of other materials such as wood or marble at a lower cost. They can also be used for ceiling materials, and are a lightweight, easy-to-install option with good acoustic performance.

2.Other Applications

(1)Stationery applications: The transparency and rigidity of GPPS flakes allow them to be used in the production of some stationery products, such as rulers, protractors and transparent folders.

(2)Toy applications: In the toy industry, the safety and durability of GPPS allows it to be used in the production of some toy parts, such as transparent windows in model toys or packaging for small toys.

PC-Optic-Sheet-Extrusion-Line.jpg)