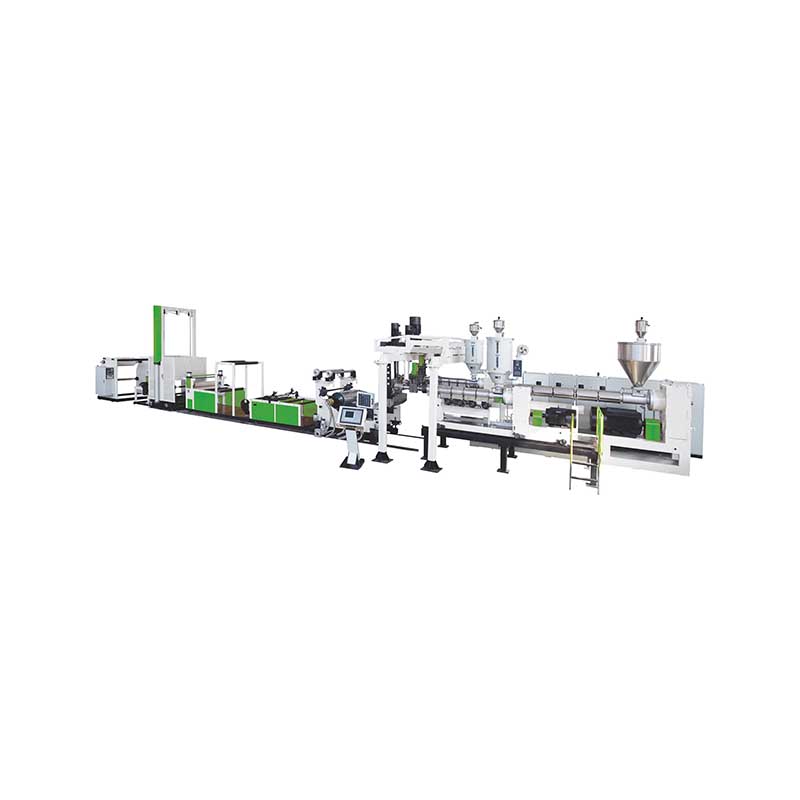

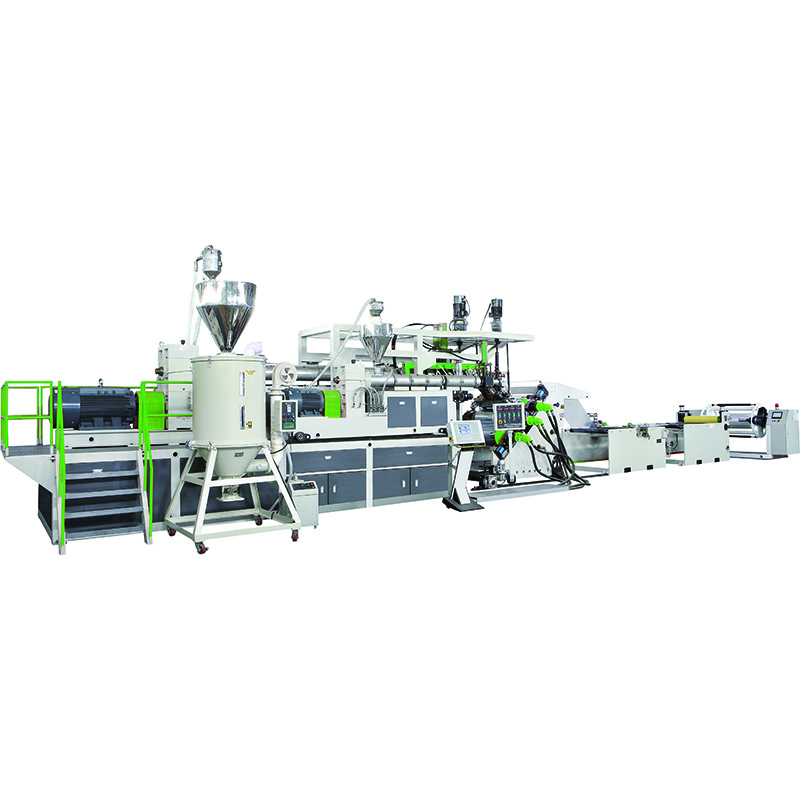

The PC, PP, PE Plastic Hollow Cross Section Plate Extrusion Line offers versatile solutions for producing lightweight, durable, and high-performance plastic plates widely used across various industries. These hollow plates are particularly popular in packaging, construction, and advertising due to their excellent impact resistance, thermal insulation, and chemical resistance properties. The extrusion line caters to diverse market needs by processing polycarbonate (PC), polypropylene (PP), and polyethylene (PE), materials that are highly regarded for their flexibility, strength, and cost-effectiveness. Its capacity to manufacture hollow plates in different cross-sectional profiles adds value for customers in industries like logistics, automotive, and agriculture, where high-quality plastic components play a critical role.

Several renowned companies like Shanghai Yike, Jiangsu Risheng, Taiwan Yisheng have adopted this extrusion line, benefiting from its ability to deliver consistent product quality and reduce production costs. A notable case involves a collaboration with a major packaging company Zhejiang dongyang plastic Co. Ltd which saw significant efficiency gains and increased production capacity after integrating the extrusion line into their manufacturing process. The line’s flexibility allows manufacturers to produce custom plate sizes and shapes to meet specific requirements in sectors such as automotive components, protective packaging, and even solar panel framing. Furthermore, the success stories of companies leveraging this advanced technology serve as a testament to its reliability and adaptability in various production environments.

In terms of research and development, the extrusion line utilizes state-of-the-art technology, including advanced temperature control systems, precision-driven screw designs, and optimized die configurations, ensuring the production of high-quality hollow plastic plates. The development team continuously invests in R&D to enhance extrusion speed, material handling, and energy efficiency, leading to reduced operational costs and environmental impact. The line is equipped with automation features that streamline production processes and ensure minimal wastage, aligning with sustainability goals. This makes the extrusion line particularly attractive to companies prioritizing eco-friendly manufacturing practices.

From a production perspective, the extrusion line demonstrates substantial capacity, with production facilities capable of handling large-scale orders while maintaining excellent product quality. The production lines are capable of generating thousands of square meters of hollow plastic plates per day, with advanced storage systems that ensure quick and efficient stock management. The high production volumes, combined with rigorous quality control processes, guarantee that products meet international standards, such as ISO 9001. Inventory levels are consistently monitored to ensure sufficient stock for rapid order fulfillment, minimizing lead times for clients. Additionally, product customization options include varying plate thicknesses, colors, and surface treatments, allowing manufacturers to tailor their products to meet specific industry standards and customer needs.

PC-Optic-Sheet-Extrusion-Line.jpg)