Why we choose PLA material?

PLA is a transparent, non-toxic, and biodegradable environmentally friendly material, made from renewable resources and commonly used in the production of the following products:

Due to its good transparency and biodegradability, PLA material has become a popular choice for many environmentally friendly catering enterprises to produce disposable tableware such as plates, knives, forks, spoons, bowls, cups, straws, etc; Packaging film for fruits, vegetables, cooked food, candies, snacks and other foods; Packaging containers such as takeaway food boxes, takeaway bags, and ready to eat packaging bags; Used for transparent packaging boxes of cold drinks or fruit salads, beverage bottles, juice bottles, etc. PLA bottles, although not as strong as PET bottles, are suitable for packaging low-temperature, non carbonated beverages; Surgical kits, disposable syringes, wound dressings, drug packaging and other medical and hygiene products, PLA’s biocompatibility makes it have certain applications in the medical field.

In summary, PLA’s versatility, biodegradability, and environmentally friendly properties make it an ideal choice for a wide range of products, particularly those used in the food service, packaging, and medical industries.

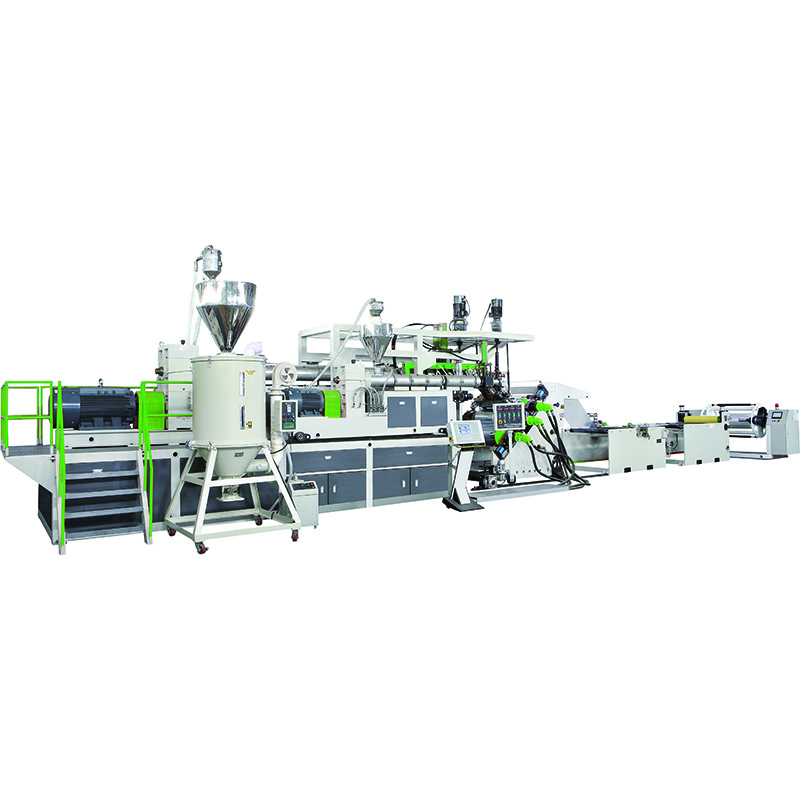

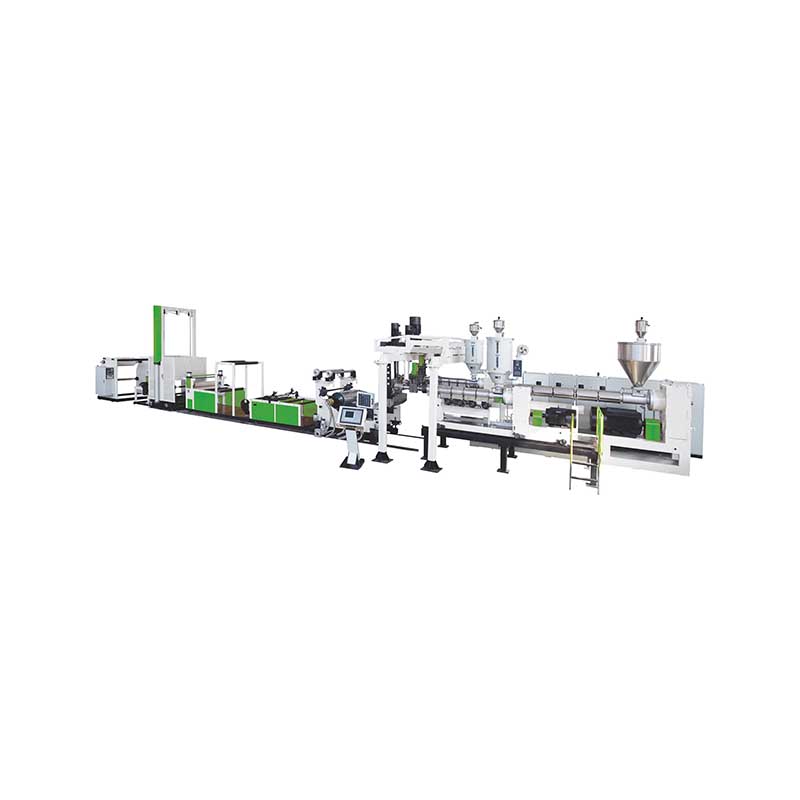

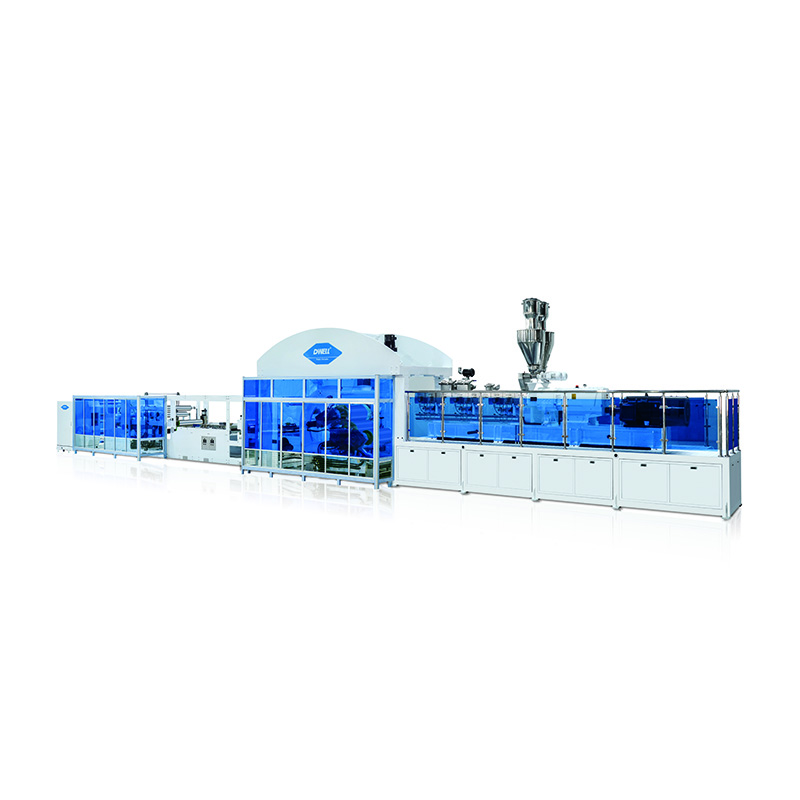

Why choose our extrusion line machine?

High Automation:

The PLA extrusion production line features modern design principles and is equipped with an advanced automation control system. Through computer-programmed control, the entire production process—including parameters such as temperature, speed, and pressure—can be automatically adjusted, enhancing production stability and efficiency.

Energy-Efficient and Environmentally Friendly:

The line incorporates optimized design and efficient heating and cooling technologies to minimize energy consumption. A waste recycling system is also implemented to recover offcuts and defective plastic during production, reprocessing them into new raw materials. This reduces resource waste and contributes to environmental protection.

High Flexibility and Multifunctionality:

The production line is equipped with various auxiliary devices, such as mixers, die heads, cooling systems, traction units, and winding equipment, allowing for the production of different types of packaging materials (e.g., films, bags, sheets, etc.). The die heads and accessories can be quickly changed to accommodate different product requirements, improving the flexibility of the line. Additionally, the equipment supports features such as biaxial stretching and co-extrusion, enabling the production of multi-layered packaging materials that enhance both performance and adaptability when using materials with different colors and properties.

Consistent Product Quality and Stability:

Thanks to precise extrusion processes and high-quality equipment, the plastic packaging materials produced exhibit uniform thickness, stable dimensions, and smooth surfaces, meeting the high-quality standards required for premium packaging applications.

Adjustability and Customization:

The production line allows for the adjustment of material thickness, strength, transparency, and other parameters according to customer specifications, catering to the diverse needs of various packaging types.

Easy Maintenance:

The equipment is designed for easy daily maintenance and upkeep, minimizing downtime and ensuring consistent operation throughout the production process.

TPU-Casting-Film-Production-LINE.png)