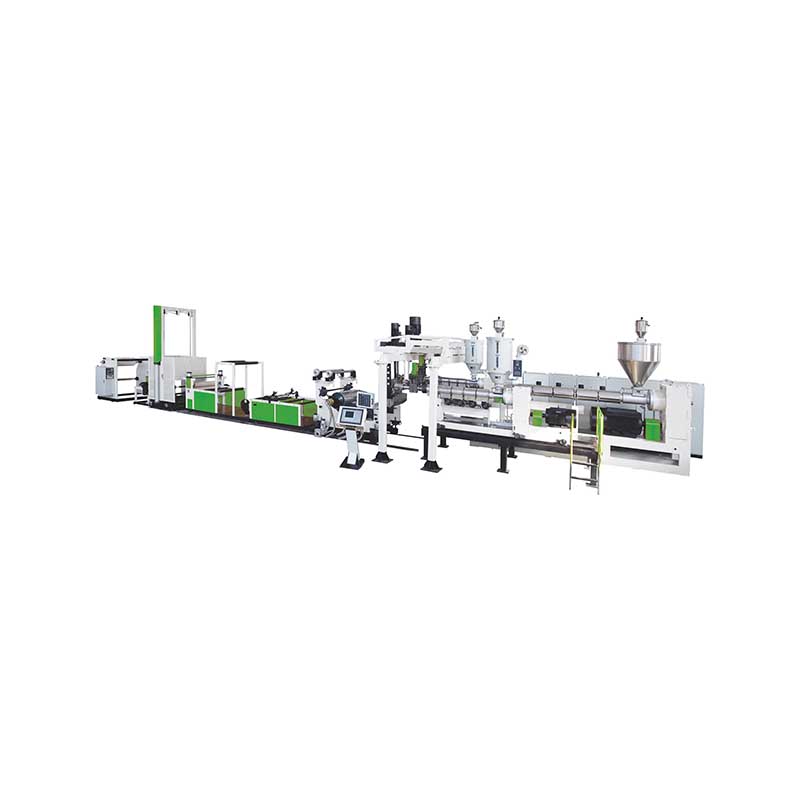

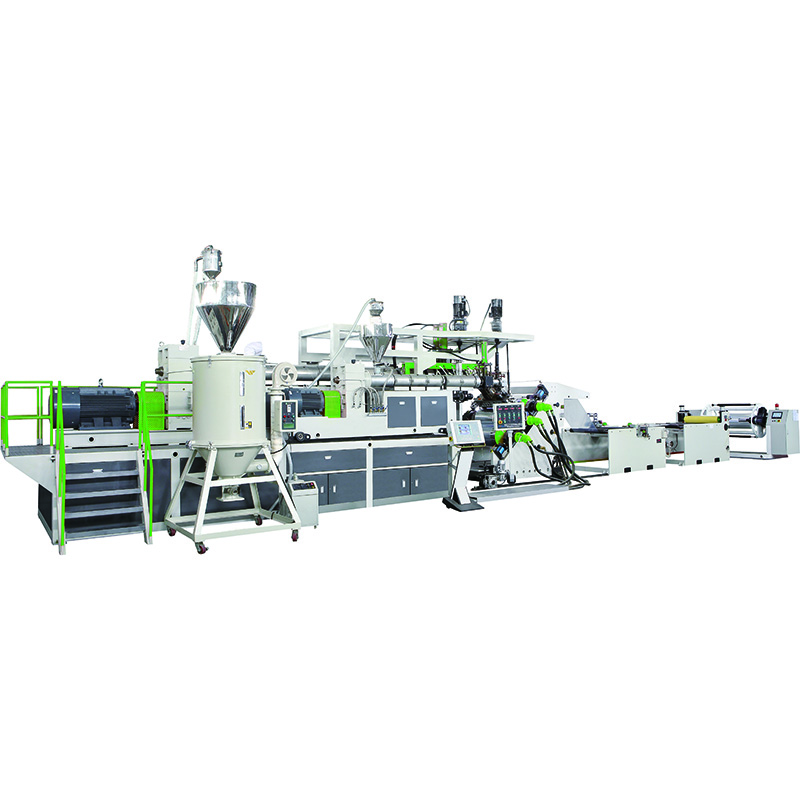

PP sheet production line is a special equipment system for the production of polypropylene (PP) sheet, widely used in packaging, construction, home furnishing and other industries. In the production process, the polypropylene resin is melted through heating, through the extruder, mold, cooling, traction and cutting, and finally form the required thickness and width of PP sheet. The following are the main components and processes of the PP sheet production line:

Extruder: the polypropylene particles are melted and squeezed out, and the molten resin is evenly transported to the mold through the rotation of the screw.

Mold: For molding, control the width and thickness of the sheet. The design of the mold directly affects the flatness and thickness uniformity of the product.

Cooling system: usually using water cooling or air cooling, the newly squeezed PP sheet quickly cooling, so that it is molding.

Traction device: control the thickness and stability of the sheet through mechanical stretching to ensure that the sheet does not deform.

Cutting system: Cut the cooled long sheet to the desired length for easy packaging and subsequent processing.

Winding device: for film products, the sheet is rolled up through the drum for easy storage and transportation.

Advantages of PP sheet:

1,High hardness and high melting point.

2, lower thermal distortion temperature (100℃), low transparency, low gloss, low rigidity.

3, the impact resistance strength is high, and the strength of PP increases with the increase of ethylene content.

4, has excellent hygroscopic resistance, acid and alkali corrosion resistance, dissolution resistance.

Advantages of DWELL PP sheet line:

1.Efficient production Continuous production: PP sheet production line can achieve efficient continuous production to meet the demand of mass production. Equipment configuration is reasonable, high degree of automation, can greatly improve the production efficiency. High output: Through advanced extrusion process and optimized design, PP plate production line can produce a large number of plates in a relatively short time to meet the rapid market demand.

- Excellent product quality Uniform thickness and width: the advanced mold design and precise control system can ensure uniform thickness and width, and ensure the stability of the final product quality. Good: through the cooling system optimization, can ensure that the plate surface is smooth, not easy to warp deformation.

- Energy saving and environmental protection Low energy consumption: PP board production line adopts efficient heating and cooling system, which reduces energy consumption and reduces production cost.

- Cost control

Low raw material consumption: the efficient extrusion technology of production lines can reduce the waste of polypropylene raw materials, thus effectively reducing the production cost.

- Strong flexibility

Diversified product production: PP sheet production line can adjust parameters according to different requirements, and produce sheets with different thicknesses, width and characteristics to meet various market demands.

- Durability and stability

Long-term stable operation: high-quality equipment and precise process design ensure the long-term stable operation of the production line, reduce downtime and maintenance frequency, and improve the service life of the production line.

High mechanical strength: high-strength equipment and materials are used in the production process to ensure that the production line can still maintain high efficiency and stability under high load.

- Extensive application areas

Multi-industry application: PP sheet production line can be used to produce a variety of industries, including packaging, construction, home, advertising and automotive industries. It is suitable for manufacturing food packaging, advertising boards, partitions, curtains, furniture and other products.

- Convenient maintenance and operation

Easy to operate: modern PP sheet production line is usually equipped with digital control system, the operation interface is simple and easy to understand, easy for operators to master.

Convenient maintenance: the equipment design considers easy cleaning and maintenance to ensure smooth progress in the production process and reduce the failure rate.

- Innovate technologies

High precision control technology: using advanced extrusion, traction, cooling and cutting technology, can achieve more refined production control, further improve the quality of the sheet.

Intelligent system: The modern PP sheet production line is also equipped with an intelligent monitoring system, which can monitor the production status in real time, and automatically adjust according to the needs to optimize the production process.

application :

Packaging industry: used for the manufacture of food packaging, daily packaging, etc.

Construction industry: used as building decoration materials, waterproof film, etc.

Household goods: such as furniture boards, storage boxes, etc.