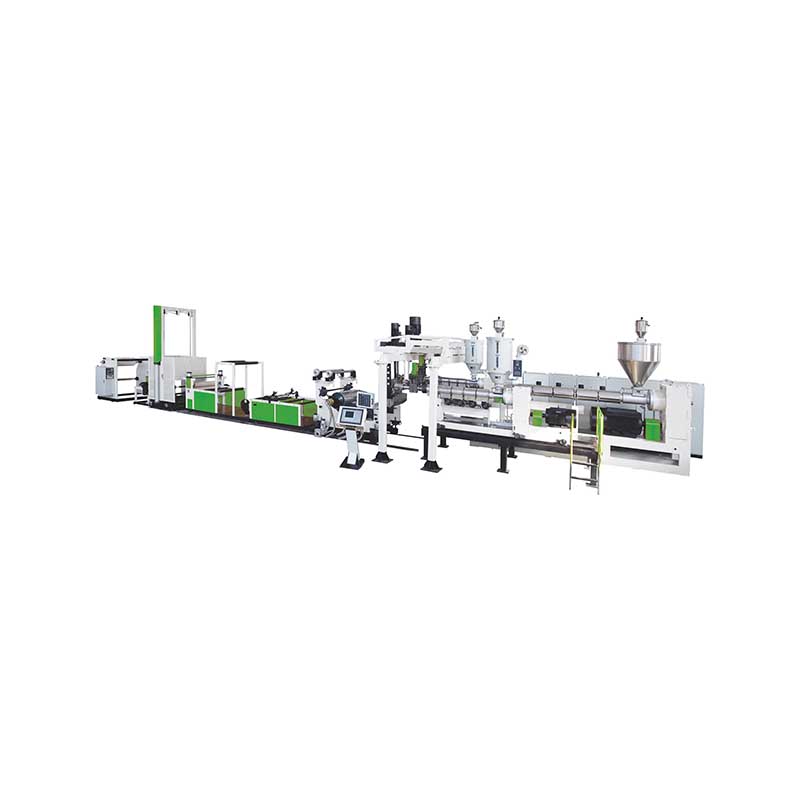

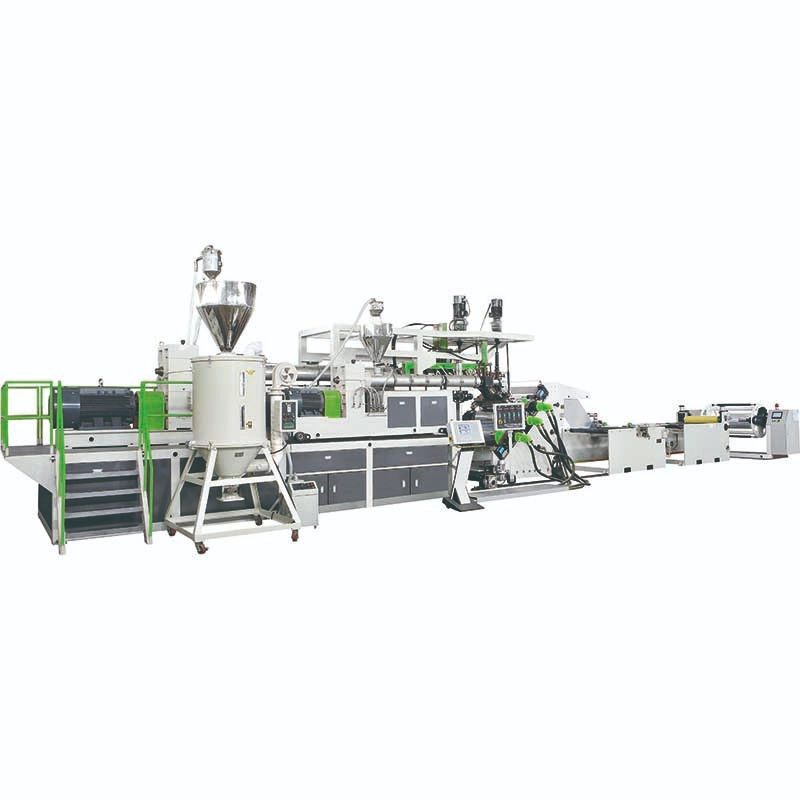

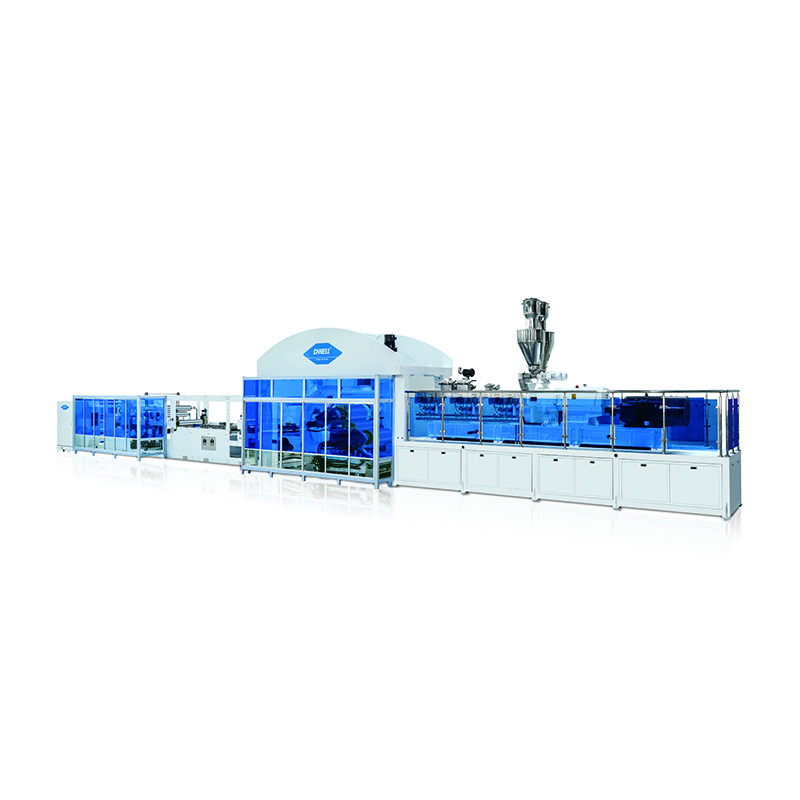

Production process flow:

Raw material preparation and mixing: the polymer materials such as polyether ether ketone (PEEK) are evenly mixed with the necessary additives to prepare the basic raw materials required for the production of SGP film.

Extension molding: the mixed raw materials are molded, and the thickness and uniformity of the patented extension system is used to control the film, solving the problem of mucosa and stripping in the traditional process.

Low temperature plasticizing and cooling: plasticizing through the low temperature flow extension system to prevent the aging caused by high temperature under the condition of ensuring the material performance, and then cool the film.

Online stress removal treatment: the online stress removal device is integrated in the production line to eliminate the internal stress generated by the film during the cooling process, and improve the stability and service life of the finished product.

Rolling and cutting: The cooled SGP film is rolled uniformly under the action of the tension control system and cut into specific sizes according to customer needs.

Quality inspection and packaging: the finished product thickness, transparency, tensile strength and other indicators to ensure that the quality of the film meets the standards, and then packaging and shipment.

Advantages of SGP film production line equipment:

- Automatic weighing type metering device to ensure a variety of solid and liquid additives and raw material high-precision feeding. SGP belongs to the ionic type middle layer consisting of an ethylene-methacrylic acid copolymer with a small amount of metal salts.

- The low-temperature flow extension system ensures the good performance of the film under the condition of full mixing and plasticizing.

- The special design of the extension part solves the problem of mucosa and stripping.

- Unique online tempering and stress removal device.

- Multiple tension control systems in the production line can smoothly transfer the elastic sheet in the process of cooling, traction and rewinding.

- Siemens PLC and industrial control machine are under centralized control, which can easily realize closed-loop control.

Advantages of the SGP film:

1, high transparency: the light transmittance of SGP film is up to 90%, you can clearly see the protected object, and will not affect its original color and luster.

2, excellent weather resistance and chemical resistance: SGP film has good weather resistance and ultraviolet resistance, not easy to aging and discoloration; and it is also chemical resistance, not easy to corrosion, long-term stable performance.

3, scratch-resistant: SGP film has a certain hardness and scratch-resistant performance, which can effectively protect the patch from scratches and wear.

4, good processing: SGP film has good flexibility and processing, easy to bend and paste, suitable for a variety of different shapes and sizes of the paste.

5, safety and environmental protection: SGP film does not contain harmful substances, safe and environmental protection, can be recycled.

Main Application:

- Construction field: SGP film can be used for the bonding of building laminated glass to improve the strength and stability of the glass. At the same time, SGP film can also be used for building glass curtain wall, ceiling glass, bank glass, stair glass and other fields of sealing and protection.

2, automobile manufacturing field: SGP film can be used to manufacture automobile water pipes, fuel pipes, seals, etc. Its excellent chemical corrosion resistance and high temperature resistance make SGP film can maintain good performance for a long time.

- Medical field: SGP film is widely used in the manufacture of medical devices due to its good biocompatibility and chemical corrosion resistance, such as medical equipment can maintain good performance in the process of use.