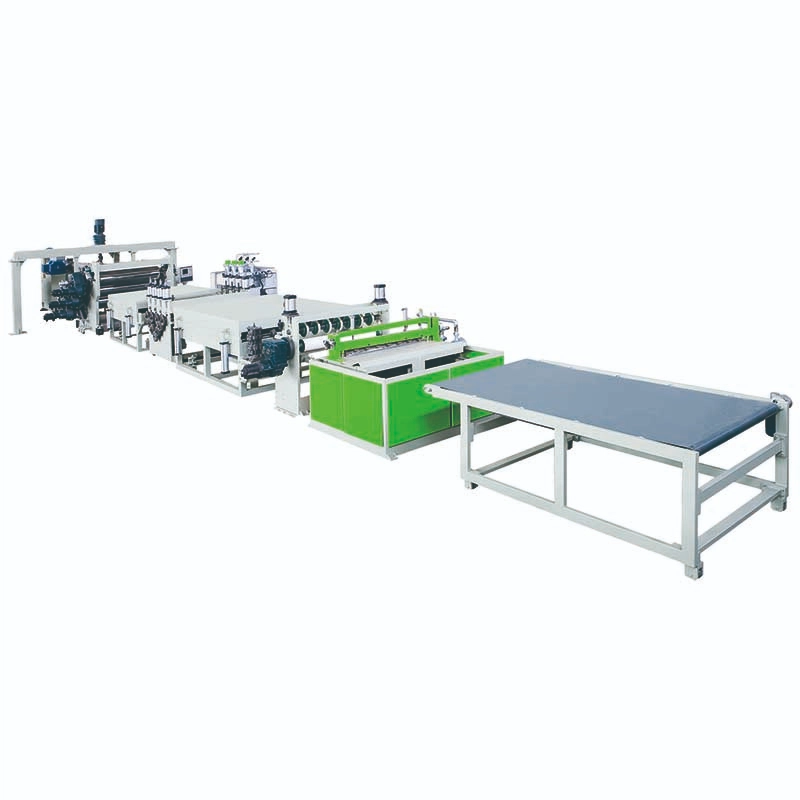

Sheet Extrusion Line Process Flows

Extruder —- Screen changer —–Melt pump —– T-die —— Calender —– Cooling bracket —– Haul-off—- winder

The core principle of this production line is efficient plasticization, mixing, and venting within the twin-screw extruder, avoiding traditional drying and crystallization processes. The venting system removes moisture and volatile substances, ensuring that the material retains high-quality physical properties when entering the cooling and forming stages, thus guaranteeing the excellent performance of the final product.

Key Features of Twin Screw Dryer-Free Vented PET Sheet Extrusion Line:

- . Process Simplification: This line equipped with degassing system, and no need drying & crystallizing are required, simplifying the production process and reducing operational complexity and costs.

- . Energy Saving: PET sheet single screw extrusion line adopts advanced technology to greatly improve its comprehensive capacity, and has the characteristics of low energy consumption, simple process, convenient equipment use and maintenance.

- Versatility: The twin-screw extruder can handle various formulations and additives, providing flexibility for different production requirements.

- . Precise Temperature Control: The cooling system can effectively control the temperature of the sheet and ensure the quality of the sheet

- . High Output: Capable of processing large volumes of material at high speeds, making it suitable for large-scale production.

- .T-Die: Its design and manufacturing directly affect the quality and performance of the sheet. The extrusion die can produce PET sheets of different thicknesses, widths and shapes by adjusting the structure and size of the die.

Characteristics and Advantages of PET Sheets:

- .Crystal Clear Transparency: PET plastic stands out for its remarkable transparency, making it an excellent material for manufacturing clear packaging items like bottles, boxes, and containers.

- . High Heat Resistance: With its ability to withstand elevated temperatures, PET plastic is ideal for packaging hot foods and beverages without risk of warping or breaking.

- . Exceptional Strength and Durability

Known for its rigidity and mechanical strength, PET plastic ensures the production of long-lasting and sturdy products that can endure heavy use.

- .Superior Chemical Resistance: PET plastic resists a broad range of chemicals, making it particularly well-suited for storing cosmetics, pharmaceuticals, and other chemical-sensitive products.

- . Environmentally Friendly and Safe:As a non-toxic, odorless material with excellent hygienic properties, PET plastic is perfectly safe for direct food packaging applications.

- .Excellent Electrical Insulation: PET plastic provides outstanding insulation against electricity and maintains its stability under varying temperature conditions.

Line component(pictures)

Applications of PET SHEETS

PET sheets are versatile and widely used in various industries due to their excellent properties. Some common applications include:

(1). Packaging

PET sheets are extensively used in packaging, particularly for food and beverage packaging, due to their transparency, durability, and resistance to moisture. They provide excellent protection for products while offering high visibility for the consumer.

(2). Thermoforming

PET sheets are commonly used in thermoforming processes to create packaging trays, clamshells, and containers. Their ability to be heated and molded into different shapes makes them ideal for producing complex and precise shapes.

(3). Displays and Signage

PET sheets are often used for display and signage purposes because of their clarity, rigidity, and ease of fabrication. They are commonly used for point-of-sale displays, window signage, and promotional materials.

(4). Medical and Pharmaceutical Packaging

PET sheets are widely used in the medical industry for the packaging of sterile products and medical devices. Their chemical resistance and ability to maintain structural integrity make them a safe and reliable choice for healthcare applications.

(5). Industrial Applications

Due to their strength and durability, PET sheets are also used in various industrial applications, including protective covers, machine parts, and components that require high impact resistance.

Why Choose DWELL Machinery?

DWELL Machinery is a professional plastic extrusion machinery manufacturer in China that integrates production, processing, sales, and service. The company currently has two major production bases in Dongguan, Guangdong and Chuzhou, Anhui. The total area is about 100000 square meters, with over 200 technical and management personnel.

DWELL Machinery will continue to adhere to the quality policy and direction of “excellent quality, perfect as one”! Remember the core concept of “honesty towards others”, develop new products for the company, improve the quality of existing products, and continuously strive to provide after-sales service!

Providing Better After-Sales Service.

(1). Timely Response and Communication

Customers may encounter various issues after purchasing products, so responding quickly to inquiries and complaints is key to after-sales service. Providing quick responses through phone, email, or online chat ensures that customer problems are addressed promptly.

(2). During chief – equipment installation the Seller will conduct training of the technical specialists of the Buyer to the operating regulations, service and maintenance of the equipment.

(3). Maintenance and Repair Services. Providing free repair services during the warranty period and addressing faults efficiently is important. After-sales service should also include regular maintenance and inspection to extend product life and prevent potential issues.

Single-Screw-Dryer-Free-Vented-PET-SheetPlate-Extrusion-Line.jpg)

Twin-Screw-Dryer-Free-Vented-PET-Sheet-Extrusion-Line.jpg)