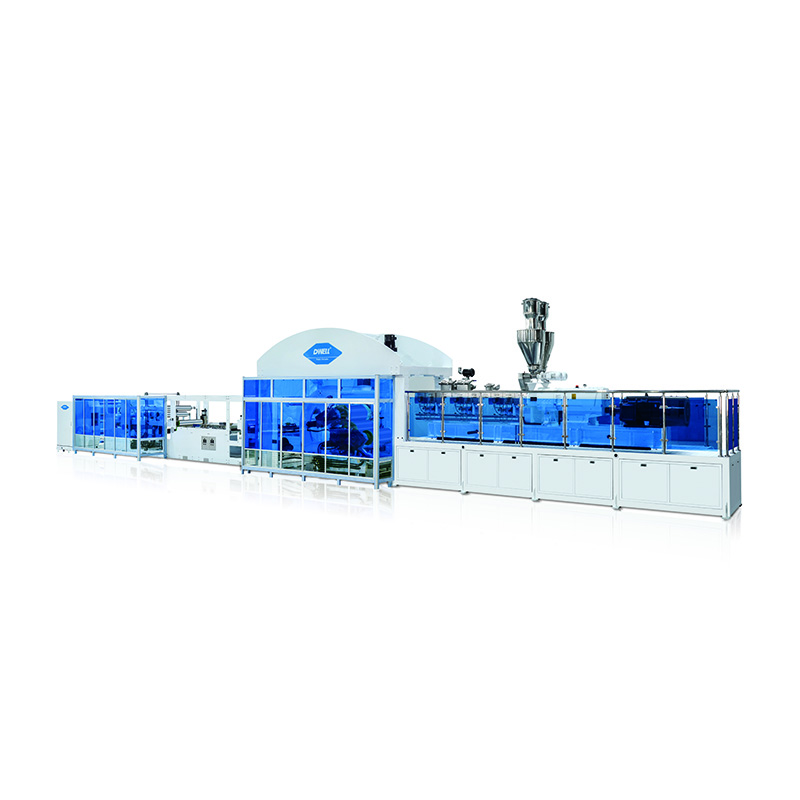

1.Overview of Essential Components

1.1 The Extruder

At the heart of the entire production process lies the extruder. Utilizing a sophisticated single-screw design, it effectively plasticizes the ABS raw material and extrudes it into a thick plate of specific dimensions and form. The extruder is equipped with an imported temperature control meter and a refined heating system, enabling it to heat the raw material swiftly and uniformly. Furthermore, it incorporates an advanced variable frequency speed control system, which continuously monitors and adjusts the production settings to ensure the production of high-standard plates.

1.2 The Mold

As a vital tool in product molding, the mold plays a crucial role in cooling and shaping the extruded ABS melt. To enhance the precision of thickness control, Dwell’s ABS thick plate extrusion production line features a mold with a unique double throttling design and high-precision manufacturing techniques. The mold material has undergone rigorous selection and testing, possessing exceptional corrosion and wear resistance. This ensures the mold’s stability and durability, thereby reducing maintenance and replacement costs.

1.3 The Cooling Mechanism

The cooling system of Dwell’s ABS thick plate extrusion production line employs cutting-edge cooling technology and efficient heat dissipation devices to rapidly cool the extruded ABS melt. This allows it to uniformly solidify into a stable ABS thick plate while maintaining its dimensions and shape. Key components of the cooling system include cooling water tanks, cooling rollers, and nozzles. Designed with intelligence, the system can automatically adjust parameters based on production requirements, further enhancing product quality.

1.4 Tractor System Compositional Features

The tractor system, in itself, constitutes an integral part of Dwell’s ABS thick plate extrusion production line, whereby one can notice a really hard work of imagination in its design. It has an operating velocity that is just perfect, with accurate controlling. This ensures complete assurance of uniform tension, size, and surface quality along the whole length of the extruded plates. The system has been flexible enough to align it perfectly with production requirements, thus allowing the process of continuous plate extruding without disruption. Equipped with advanced sensors and a full set of monitoring systems, the tractor will be able to guarantee stability and safety for the production line while constantly monitoring its working status.

1.5 Segment Cutting Equipment

Apparatus designed for the purpose of cutting, the machinery cuts the extruded ABS thick plate into individual plates to desired length. Equipped with advanced blade technology and an accurate cutting control mechanism, it cuts the thick ABS plate quickly and accurately to meet the specified requirements in production. The wear resistance maintains the sharpness of the blades, further enhancing efficiency and increasing the rate of utilization for plates. It also includes intelligent cutting parameter tuners integrated inside, which immediately self-adjust according to plate characteristics for the sake of accuracy and flatness of the resulting cut surface.

2.Production line characteristics and advantages

2.1High production efficiency

The entire process can be monitored and regulated by the automatic control system adopted in Dwell’s ABS thick plate extrusion production line. The core equipment-extruders, molds, cooling systems, traction machines, and cutting machines-make use of advanced technology and optimal design, achieving continuous and smooth production, hence greatly improving the production efficiency and reducing the production cost.

2.2 Consistently deliver quality products

The Dwell ABS Thick Plate Extrusion Production Line enables plates to meet strict manufacturing requirements, such as excellent mechanical and electrical corrosion resistance. The stability and durability of the plates are at an industry-leading level due to the high-precision mold and control system equipped for its production, assuring the product in dimensional correctness and surface quality.

2.3 Highly adaptive

Due to the fact that every customer’s needs are different in terms of plate thickness, breadth, and length, the Dwell ABS thick plate extrusion production line is allowed to flexibly customize and adjust its extrusion process parameters to cater to the needs of customers. In this way, better services can be rendered by tailoring design and manufacturing for customers.

2.4 Fields of Application

Due to being combined with so many advantages, the thick plate basic production line has very extensive applications in many industries. With excellent mechanical properties, resistance against chemicals, impact, processing performance, and electrical insulation performance, the ABS plates are ideal for industries in home appliances, vehicle components, photovoltaics, and baggage blisters. The car industry uses ABS thick plates to manufacture body shells, dashboards, and interior panels, all these increasing the comfort and safety of the vehicle. ABS plates are used in the electronics and electrical appliance industry in improving appearances for better looks and strengths in the manufacture of TV shells, computer shells, home appliance shells, washing machine outer shells, and parts amongst others. ABS plate can be used in interior decorative materials such as wallboard and ceiling in the building industry. It can also produce all kinds of package boxes, cases of luggage shell, display rack, and so on in the packaging industry. Thick ABS plate can be applied to the production of necessary parts in the photovoltaic industry such as the pads of solar panels.

2.5 Wide applicability

The thick plate extrusion production line for ABS at Dwell can make ABS plates of various thicknesses and standards to meet the demand of different industries. There are proper application situations in many industries, including the automobile sector, electronic appliance sector, construction sector, packaging sector, etc.

3.Application Fields

Due to the great mechanical, chemical, and electrical insulating qualities, ABS plates find broad employment in many different industries. Automotive industries use thick ABS plates for making the dashboard, body shell, and other parts. The electronics industry uses it in great quantity for making TV shells and other household appliance shells. The building sector is also one of its large users in interior decoration materials such as wall panels and ceilings. The packaging industry makes a great variety of packaging boxes and display racks up to the demanders’ requirements.

4.Assistance and Assistance

Certain of the diverse range of services and support which Dwell offers to its clients include pre-sale consultation, installation, and commissioning, technical training, as well as after-sales service. In the stage of pre-sales consulting, detailed products introductions and solution design will be provided for the customers by the company. During the installation and commissioning stages, skilled technicians are dispatched for on-site supervision and operation training. Regarding after-sales service, timely technical support and maintenance services will be provided in the normal operation process of the production line to meet the customer’s requirement.

Moreover, Dwell provides specialized service solutions for customers based on their diversified needs. The company may dynamically adjust and optimize the product design, manufacture, installation, and commissioning process in accordance with the real needs of customers for more considerate services.

TPU-Casting-Film-Production-LINE.png)

Twin-Screw-Dryer-Free-Vented-PET-Sheet-Extrusion-Line.jpg)