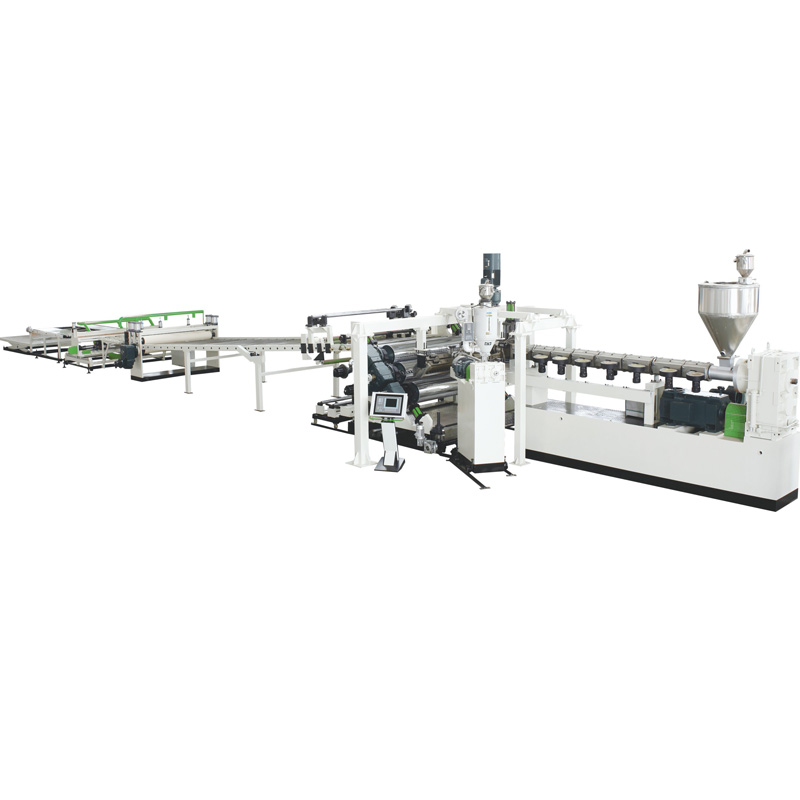

Line Process Flows:

Extruder —— Screen changer —— Melt pump —— T-Die —— Calender —— Thickness Scanner —— Cooling Bracket —— Cutting Knife —— Haul-off —— Winder

Extruder:

– Single-Screw or Twin-Screw Extruder: Melts and homogenizes the PETG material.

– Barrel and Screw: Designed for optimal mixing and melting of the material.

– Heating Elements: Maintain precise temperature control to ensure consistent material flow.

Screen Changer: Filters out impurities from the molten PETG.

Melt Pump:

-Ensures a consistent and controlled flow of the molten plastic to the die.

Calendering Unit:

– Three-Roll Calender: Comprises a series of heated and polished rollers that smooth and shape the sheet, controlling its thickness and surface finish.

– Gap Adjustment Mechanism: Ensures precise control of sheet thickness.

Cooling System:

– Cooling Rollers: Gradually cool the sheet to solidify it while maintaining its dimensional stability.

– Water Baths or Air Cooling Units: Further reduce the sheet’s temperature as needed.

Haul-Off Unit:

-Draw the sheet through the extrusion line at a controlled speed, ensuring uniform thickness and preventing stretching.

Winder:

-Collects the finished film onto rolls for easy handling, storage, and transport.

Main Process Overview:

(1). Feeding and Melting: Raw PETG pellets are fed into the extruder, where they are melted and homogenized by the rotating screw and heating elements.

(2). Filtering and Pumping: The molten PETG is filtered to remove impurities and then pumped to the die at a consistent flow rate. A double-gear metering pump is used to achieve the proper melt extrusion amount, ensuring uniform melt flow and pressure stability.

(3). Calendering: The hot sheet passes through a series of calender rollers, which smooth and shape it to the desired thickness and surface finish.

(4). Cooling: The sheet is gradually cooled using cooling rollers and possibly additional cooling units to solidify and stabilize its dimensions.

(5). Corona Treatment: The sheet undergoes corona treatment to increase its surface energy, improving adhesion for printing or coating.

(6). Rewinding: After trimming, the corona-treated film is rolled into a large, wide, and high-diameter master roll.

(7). Slitting: Using an unwinding machine, the wide master roll is cut into smaller rolls of the width and length specified in the order, making it convenient for transportation and further printing processes.

(8). Haul-Off: The sheet is drawn through the production line by pull rollers, ensuring consistent speed and tension.

(9). Winding: The finished film is wound onto rolls for storage and transportation, with tension control to ensure even winding.

Key Features of PETG Furniture Decorative Film Production Line:

- . Various forms of color patterns and high-grade textures: PETG decorative film is a kind of film processed with a unique formula. With high-end printing technology and embossing technology

- . Various forms of expression: The product has natural wood texture, high-grade metal texture, elegant skin texture, high-gloss surface texture and other forms of expression.

- . Wide range of applicable materials: used for the surface decoration of furniture panels such as particle board, density board, MDF board, and European pine board, which can be processed into solid colour,high gloss,scratch resistant, skin feel, etc.

- . High Efficiency and Stable Production Capacity: The production line is optimally designed to consistently produce high-quality PETG furniture films at high speeds, ensuring efficiency and stability.

- . Environmentally Friendly : non-toxic, pollution-free, recyclable and degradable, is an excellent green and environmentally friendly material.

- . High transparency and exceptional optical: The line is equipped with precise stretching and cooling systems to ensure optimal film thickness, dimensions, and surface quality.

- . Versatility: The machine can produce a wide range of films with different layer configurations and thicknesses, depending on the specific requirements of the application. This versatility makes it an ideal choice for manufacturers who need to produce a variety of products with different specifications.

- . Intelligent Control System: The integrated intelligent control system enables real-time monitoring and adjustment of the production process, enhancing flexibility and precision.

Characteristics and Advantages of PETG Film:

- . High Transparency

PETG furniture film offers excellent transparency, showcasing high-quality visual effects, making it ideal for decorative applications.

- . Superior Scratch Resistance: The surface is highly scratch-resistant, effectively protecting the furniture’s appearance from damage.

- . Excellent Chemical Resistance: PETG film is resistant to common chemicals, making it easy to clean and resistant to contamination

- . High Toughness: It has excellent impact resistance and flexibility, making it suitable for furniture surfaces exposed to external forces.

- .Excellent Surface Quality: It features a smooth and uniform surface, providing a high-quality decorative effect. It can be processed into solid colour, high gloss, scratch resistant, skin feel, and other characteristics.

- .Recyclable and Eco-Friendly: PETG is a fully recyclable material, making it an environmentally friendly choice for sustainable packaging and manufacturing.

Applications of PETG Furniture Film: Mainly used to decorate the surface of building materials such as panels, metal, glass, aluminum profiles, etc., widely used in high-grade furniture, home appliances, cabinets, wardrobes, doors, ceilings, interior, and exterior wall decoration, elevator envelopes and other industries.