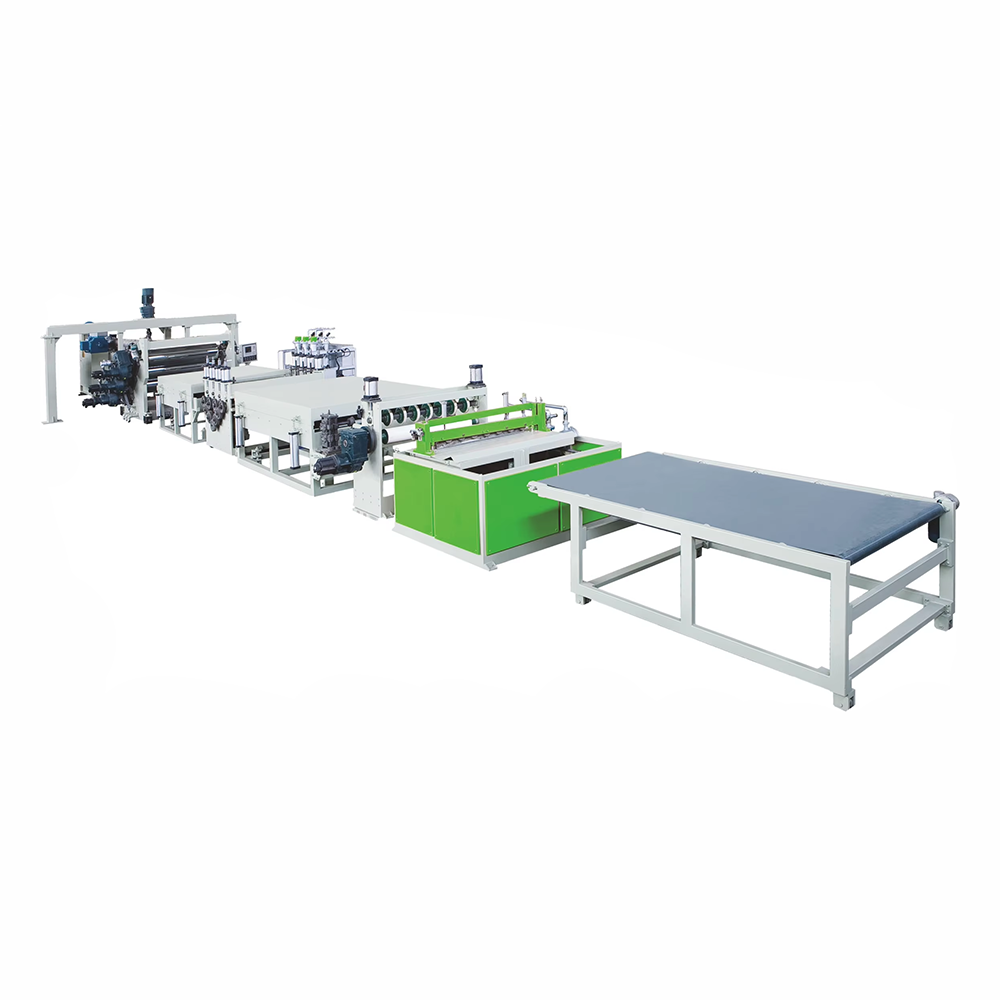

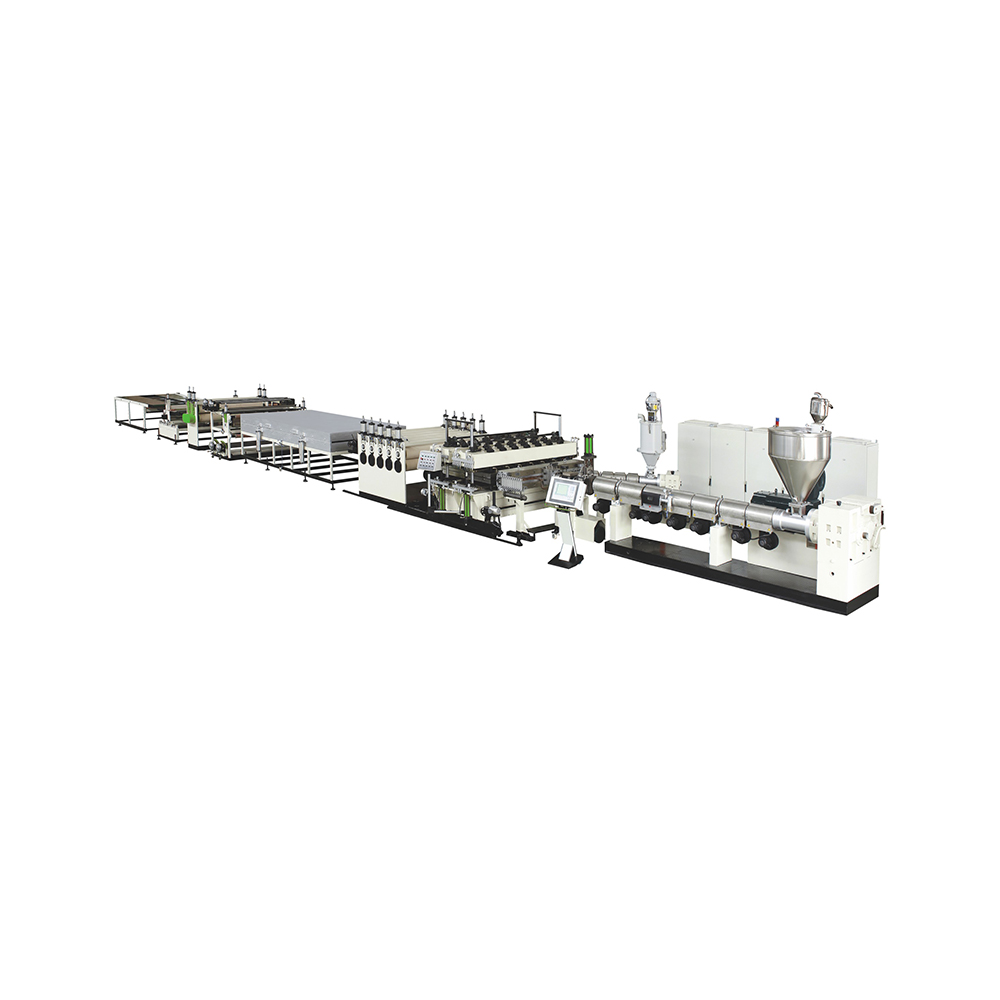

1 Main configuration of the PP Corrugated line

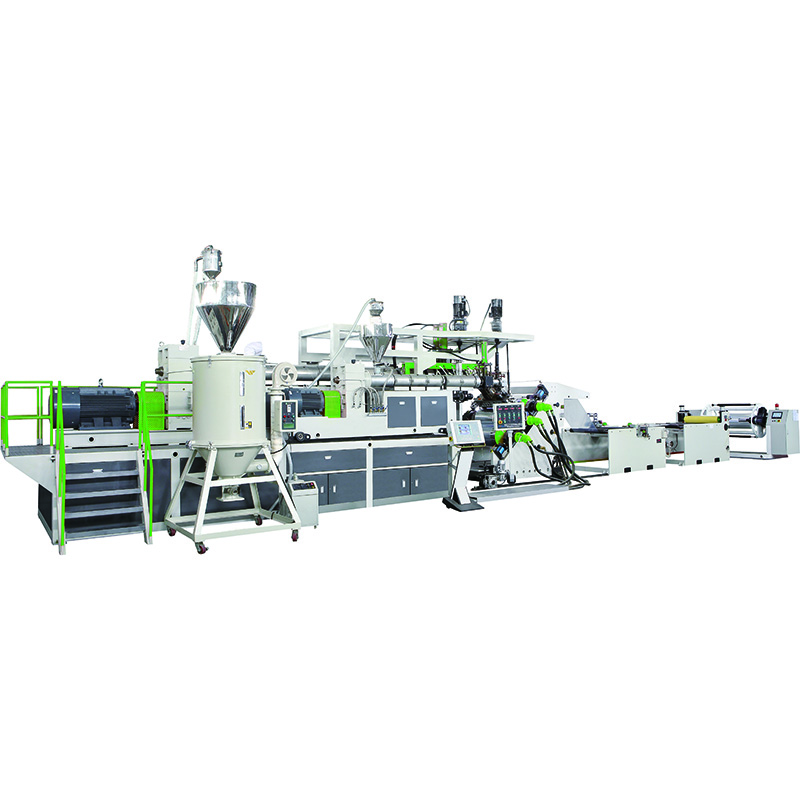

1) Extruder: Uniquely R&D screw, precise temperature control system to ensure stable plasticizing performance and extrusion efficiency, DWELL’s outstanding advantage is low energy consumption, high efficiency, high productivity.

2) Mold: Using high-quality alloy die lips and adjustable baffles to achieve even pressure distribution

3) Vacuum calibrator: The thermal convection system uses a staggered array layout to ensure accurate calibration. The calibration vacuum system contains two independent subsystems and is configured with multiple closed-loop vacuum pipelines.

4) Electrical control system: PLC controls

2.Advantages of the PP Corrugated line

1) machine head

Adopts a hanger-type flat machine head and is equipped with a pneumatic shaping mold to make the molding more reliable.

2)thermoforming machine

Equipped with a corresponding thermoforming machine, it can continuously produce various corrugated plastic tiles, and the thickness of the corrugated tiles is extremely convenient to adjust.

3)Traction roller

Adopts the same shape as the corrugated tiles The traction roller with consist.

4)Cutting

Automatic cutting makes the cut smooth and can be cut to a fixed length as needed

- Product Features

1) Wide range of thickness:The length, width, color, and basis weight can be customized according to customer requirements.

2)Lightweight material

The PP Corrugated sheet has excellent mechanical properties. To achieve the same effect, the PP Corrugated has less consumables, low cost, and light weight.

- Smooth surface

The produced PP Corrugated has a smooth surface, small dimensional error, and excellent aesthetics and practicality.

- Thermal and sound insulation

Due to the PP Corrugated Sheet, their heat and sound transmission functions are lower than those of solid boards, and they have good heat and sound insulation functions.

- Environmental friendly

The PP corrugated is easy to dispose of and will not pollute the environment. It can also be recycled into other plastic products.

- After-sales service:

Pre-sales: Our esteemed clients are welcome to consult us on various technical and business matters. We will provide relevant materials for easy reference, along with market trends, sales prices, and sales methods, to facilitate clients’ understanding of the overall market.

During-sales: After the contract is signed by both parties, the company will provide installation drawings for water, electricity, gas, and foundations of the designed equipment according to client requirements and actual conditions. Additionally, a detailed material purchase list and recommended vendors will be supplied for clients’ reference. Upon completion of equipment production, we will communicate with clients in advance to schedule a trial run at our company and provide various conveniences.

After-sales: After the production equipment has been debugged and qualified at our company, our service and debugging personnel will arrive at the client’s site within the time frame specified by the client to carry out installation, debugging, personnel training, and technology transfer until the client can independently operate and produce qualified products. For subsequent services, our service personnel will also arrive at the site within the time required by the client.

Formula and Technical Support: All production equipment provided by our company includes a free production formula, and the equipment will be debugged according to this formula. Clients can contact us for consultation on any issues that arise during production.

Equipment Maintenance and Warranty: All equipment provided by our company comes with corresponding accessories, a one-year warranty, and is accompanied by instruction manuals and maintenance manuals.

5.Application

At present, PP corrugated Sheet is domestic green and environmentally friendly products are available. It can be widely used in the chemical industry, food industry, anti-corrosion industry, purification industry, and environmental protection equipment production industry.

Product introduction:

This product is a new generation of roofing material developed using foreign technology and is specially designed for corrosive factories and heavy acid rain areas. The product is processed in one go using two-layer co-extrusion technology, with each layer having its own function.

PC-Optic-Sheet-Extrusion-Line.jpg)

Twin-Screw-Dryer-Free-Vented-PET-Sheet-Extrusion-Line.jpg)