INTRODECE:

PVB film is also called PVB film and PVB intermediate film, etc., its essence is a thermoplastic resin film, which is produced by PVB resin and plasticizer, and has the characteristics of recycling, processing and reuse. PVB film has good adhesion to inorganic glass and is the best bonding material for laminated glass. PVB film can also absorb impact energy, so that laminated glass does not produce broken pieces, has a certain safety performance, and it has a good sound insulation effect, so it is widely used in car windows, high-rise buildings, all kinds of bulletproof glass.

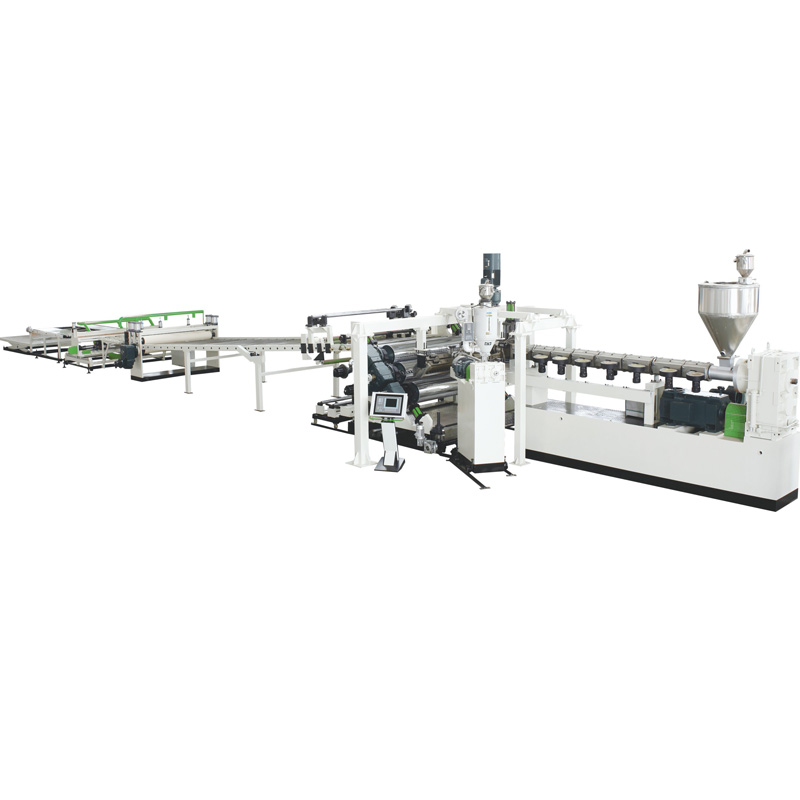

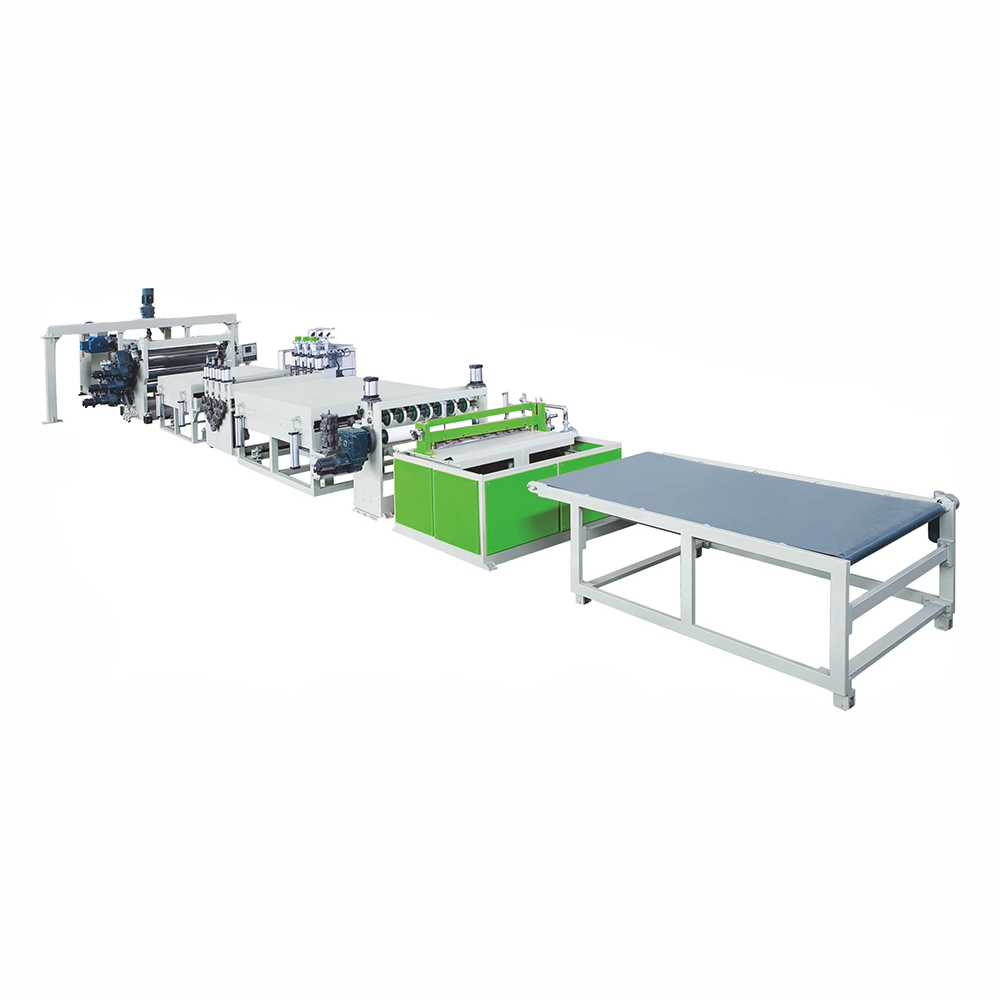

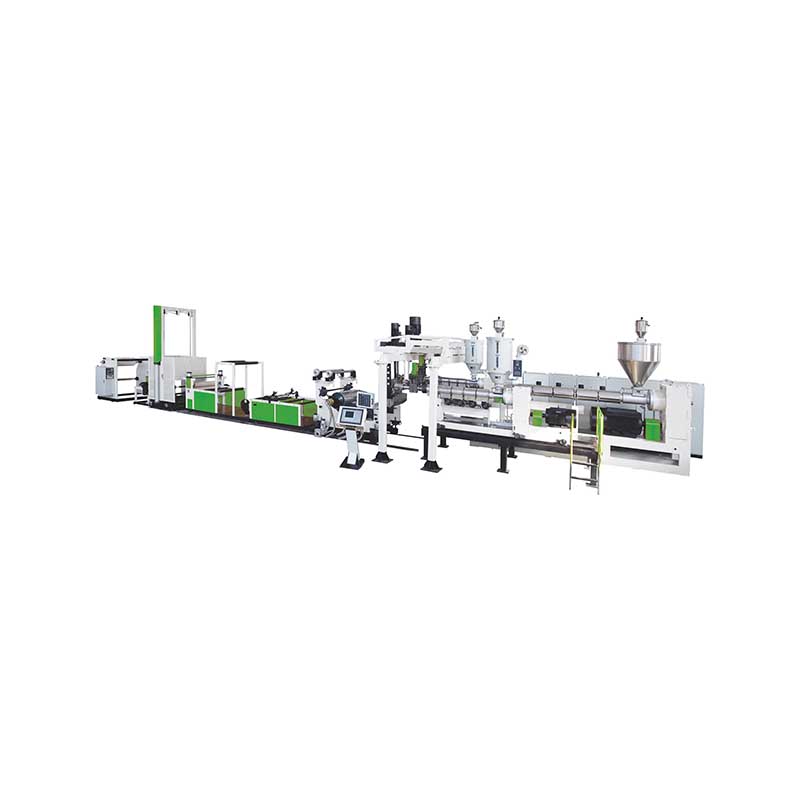

The advantages of PVB film extrusion line:

- Adapt to the different types of processing of many material systems

- From the top to the collection, automatic mixing, PLC full set of integration, can do turnkey engineering.

- Large output, low energy consumption, and high degree of automation

The advantages of PVB film:

PVB film (polyvinyl alcohol butyral film) has a variety of significant advantages, these advantages make it widely used in construction, automotive and photovoltaic fields. The following are the main advantages of the PVB film:

- Superior physical performance

Strong adhesion: PVB film has excellent adhesion to glass, metal, ceramic and other base materials. This strong adhesion makes PVB film firmly adhere to the glass debris after glass breakage, reducing the damage caused by splashing of debris.

Impact resistance: PVB film itself has excellent impact resistance, can resist the impact of external forces, and protect the safety of the glass structure.

- High safety performance

Splash prevention: In the construction and automotive fields, the application of PVB film can significantly reduce the risk of debris splashing after glass breakage and improve safety.

Good sound insulation effect: PVB sandwich glass has better sound insulation effect than ordinary glass, and can provide a better indoor environment.

- Excellent optical performance

High light transmittance: PVB film has high light transmittance, which can ensure good light transmittance and does not affect the indoor lighting and visual effect.

The refractive index is close to the glass: this allows the PVB film to maintain the clarity and transparency of the glass as a sandwich material.

- Weather tolerance and durability

Ultraviolet light resistance: PVB film can effectively isolate ultraviolet light and protect indoor items from ultraviolet light damage.

Good weather resistance: PVB film has good weather resistance, and can maintain stable performance in various climate conditions.

Long service life: According to the relevant data, the service life of the traditional building-grade PVB film can be up to 50 years or more, showing its excellent durability.

- Car glass

Front windshield, side window, rear window: PVB film is usually used in the production of automotive safety glass. It can effectively bond the glass pieces together, improve the impact resistance and toughness of the glass, reduce the debris produced when the glass breaks, so as to improve the safety of driving.

UV protection and heat insulation: PVB film can effectively block ultraviolet light, reduce the damage of ultraviolet light to the car accessories, while providing a certain thermal isolation function.

- Building glass

Explosion-proof and bullet-proof glass: PVB film can be used in the production of explosion-proof glass, bullet-proof glass and other safety glass, widely used in banks, airports, government buildings and other high safety buildings.

Laminated glass: PVB membrane is used as the core material of laminated glass, to provide the adhesion and stability of glass, and enhance the impact resistance of glass.

Sound insulation and thermal isolation glass: PVB film can improve the sound insulation performance of building glass, reduce noise pollution, and has a certain thermal isolation function, improve the energy efficiency of the building.

- Solar photovoltaic modules

Photovoltaic glass packaging: PVB film can be used in photovoltaic glass packaging.

- Aviation and aerospace

Aircraft Windows: In the aviation industry, PVB film is often used in the manufacture of aircraft Windows. It provides enhanced safety, impact resistance, and helps reduce the weight of aircraft glass.

- Home appliances and electronics

Display protection: PVB film is used to manufacture the protective film for electronic products, such as TV screen, mobile phone screen, etc., to enhance the scratch resistance and resistance to impact of the screen.

Electrical glass: In some high-end home appliances (such as refrigerator, microwave oven), PVB film is also used to improve the safety and stability of glass.

- Military and security: PVB film is widely used in the production of bullet-proof glass, such as military vehicles, security glass and other places, providing bulletproof, anti-explosion and anti-impact functions.

- Medical equipment

Medical glass: PVB film can also be used in medical devices to ensure the safety and functionality of the glass elements.

FAQS:

What kind of machine does DWELL produce?

Our main products are plastic extruder, extrusion series of line:PET single-layer co-extrusion sheet extrusion line;PP,PS single-layer/multi-layer co-extrusion line;ABS,HIPS automobile panel,refrigerator plate and bags plate extrusion line;PC,PMMA optic sheet extrusion line;PMMA,PC,GPPS plate extrusion line;PP,PE,PVC thick plate extrusion line;PP,PE,PC hollow cross section plate extrusion line;PP,EVA,EVOH,PP five-layer/seven-layer co-extrusion line,PC,PET,PVC corrugated plate extrusion line,TPU Casting Film Production Line,EVA/POE/PVB/SGP Film Extrusion line,etc.It also includes the sales and service of kinds of single-screw,double-screw,cylinder,plasticsheet/plate-die,screen changers,distributor,mirror surface roller and flower pattern roller.

Is DWELL Machinery a Manufacturer?

Yes,DWELL is a manufacturer,We own 2 manufacturing bases in Dongguan,Chuzhou China,It covers an area of 100000 square meters and has 200 technology management employees,a professional plastic extrusion and thermoforming&blister machinery manufacturer,including of R&D,designing,processing,sales and services.

How long is the delivery date?

Usually it takes about 1 – 4 months depends on different machinery upon receipt of order advance payment.

Can Dwell provide professional pre-sale service?

Yes,Dwell sale teams will provide specification according to customer’s requirements,meanwhile we can give the technical support to customers. If you need,please contact us!

Can DWELL provide after sale service?

Yes, we support our business partners by after sale service. We provide one year of free after-sales repair service,

What about the payment way?

A:By TT, L/C at sight or Alibaba trade assurance. 30% down payment should be paid after contract is valid, 70% balance should be paid before shipment.

PC-Optic-Sheet-Extrusion-Line.jpg)