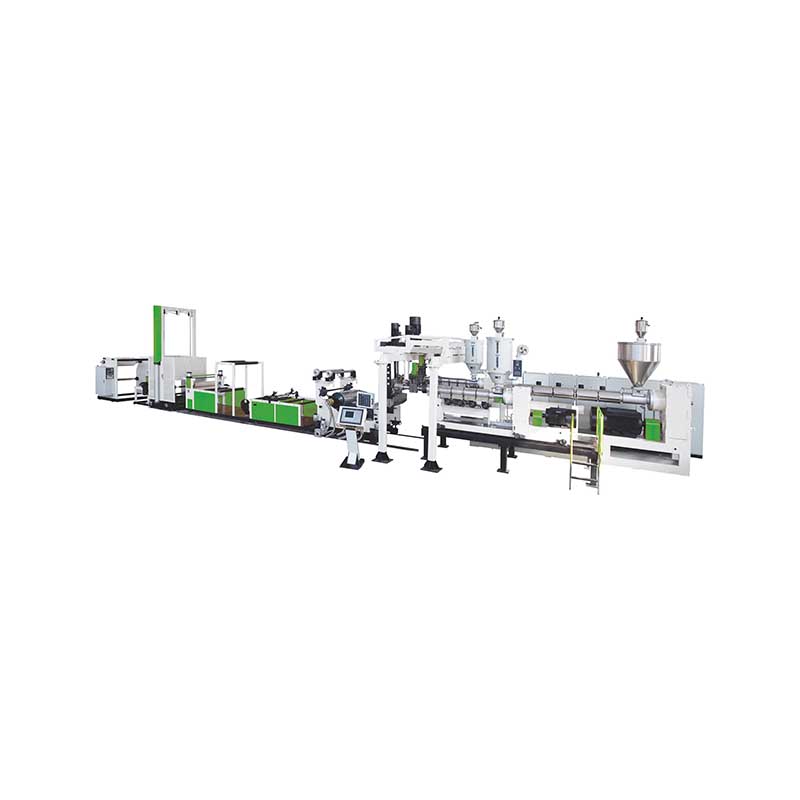

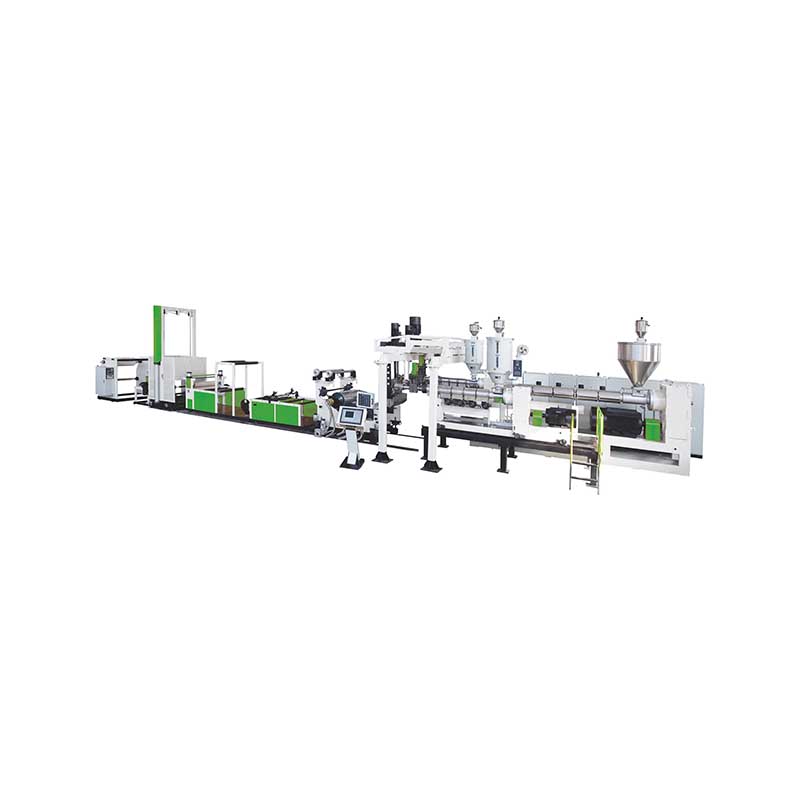

1.Production line composition

Dwell’s PVC thick plate extrusion production line is an accurate structure with comprehensive functions as the first-class production equipment in the industry. The leading role in the composition of the main key parts includes the raw material mixing system, extruder, mold, cooling system, traction device, cutting device and the control system.

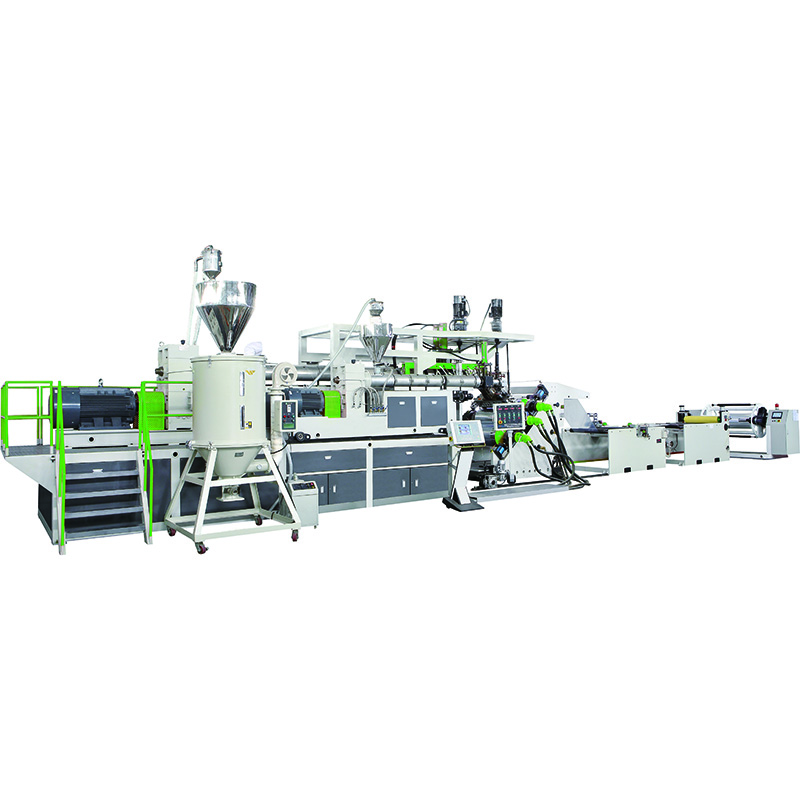

1.Raw material mixing system

The raw material mixing system is the starting point of the entire production line. Its fundamental task is to mix the raw materials in the formula, such as PVC resin, stabilizer, lubricant, and various fillers. Every system is usually equipped with a high-speed mixer and a cold mixer: the former mixes the raw materials once at high speeds, while the latter ensures the uniformity and stability of the materials by stirring them at low speeds. It will provide a very sound basis for the raw materials processed by the system with an ideal process temperature before the subsequent process of extrusion.

2. Extruder

The extruder is the central equipment of the whole production line, whose performance determines directly the quality and productivity of PVC thick plate. The extruders normally used by Dwell have a twin-screw or single-screw structure and an efficient heating/cooling system. During the course of extrusion, driven by the screw, raw materials enter the stages of plasticization, melting, mix, and exhaust to finally form a uniform melt. Full consideration is taken in designing an extruder with regard to the fluidity and extruding pressure so that PVC melt can enter into the mold and extrude smoothly into a thick plate of any desired shape.

3. Mould

The mold is a crucial condition in molding PVC thick plates. Its design and manufacturing precision determine the product’s quality.

Equipped with advanced mold design and manufacturing technology, Dwell ensures the mold has high precision and durability.

The shapes and sizes can be made into various forms according to customer needs, meeting the diversity of PVC thick plate applications in various industries. Meanwhile, material and heat treatment processes of the mold are carefully selected so that it maintains stable performance in high-temperature and high-pressure extrusions.

4. Cooling system

A cooling system is of great importance in the fast cooling and shaping of PVC thick plates.

In Dwell’s cooling system, usually water cooling or air cooling is adopted through spraying or blowing to rapidly take heat away from it.

According to the real situation of the production line, the system can flexibly make some adjustment to keep PVC thick plates in a stable shape and size in the cooling process.

Meanwhile, it saves energy and is environment-friendly in the cooling system, which can lower the energy consumption and emission during production.

5. Traction device

Traction device is used for leading the cooled and hardened PVC thick plates out of the mold continuously and automatically. Variable frequency speed regulation technology is adopted in the traction device to realize synchronous operation with the extruder. It ensures not only continuity and stability but also makes the production line easier to operate with less labor cost.

6.Cutting device

The cutting device cuts the continuously extruded PVC thick plates to the required length or size. The cutting device from Dwell adopts an automatically cutting technology that can cut accurately to the set length. This way can not only increase the production efficiency at a higher level but also guarantee great precision and uniformity to the size of the product.

7.Control system

As the core of the production line, the control system can monitor and control the production line in every particular part.

Dwell’s control system usually adopts PLC or touch screen control devices to realize precise control and adjustment of equipment such as extruders, molds, cooling systems, traction devices and cutting devices.

It improves the level of automation of the production line and reduces the difficulty of operation, labor costs while ensuring the stability and reliability of product quality. .

2.Product Features

1.Efficient and stable

Equipped with Dwell’s PVC thick plate extrusion production line, the line can continuously and stably produce high-quality PVC thick plates. The precision in design, together with efficient coordination in the various parts of the production line, means this production line can produce efficiently and steadily with the use of advanced automated control systems.

2.High degree of automation

The advanced automation control system can be equipped on the production line to realize the automation from the mixing of raw materials to the cutting of finished products. By doing so, production efficiency improves with reduced labor costs and operating difficulties, allowing production with ensured stability and reliability regarding product quality.

3.Strong adaptability

According to customer requirements, this production line can be tailored and modified to cater to the needs of various industries for PVC thick plates. Be it color, size, or shape; whatever be the need of customers, Dwell provides a customized solution.

4.The quality of the product is high.

The PVC thick plate production line adopted by Dwell owns advanced mold design and manufacturing technology with efficient extrusion and cooling systems. Ensuring the PVC thick plate produced will have excellent physical properties and appearance quality. These plates boast a lot of characteristics, including high hardness, high strength, corrosion-resistant, and aging-resistant, therefore being the favored material for most industries.

5.Energy-saving and environmental protection

The production line uses advanced energy-saving technology and green materials to minimize energy consumption and cut emissions. Simultaneously, the capacity of recyclable and reusable wastes also enhances resource utilization and environmental protection performance in the production line.

Application fields:

The PVC thick plate in wide application is produced by Dwell’s PVC thick plate extrusion production line. Many industries can use it, such as construction, chemical industry, petroleum, electroplating, water purification, environmental protection equipment, mining, medicine, electronics, communications and decoration. In the above industries, the PVC thick plate can play a very important role for the excellent physical properties and high-class appearance quality.

In the building and construction industry, the PVC thick board is a kind of building material for wall panel, roof panel, and floor. It has characteristics of light weight and high strength, fire-resistant and waterproof. It can be used in anti-corrosion materials for equipment such as storage tanks and pipelines in the chemical and petroleum industries, which have features of corrosion resistance and aging resistance.

The PVC thick board is acid and alkali resistant, corrosion resistant, and used as the lining material of equipment in the electroplating industry and the water purification industry, such as electroplating tanks and sinks. PVC thick board is used in environmental protection equipment, waste gas treatment equipment, high temperature resistant, corrosion-resistant.

In addition, PVC thick boards are widely used in mining, pharmaceuticals, electronics, and communication in the manufacturing and decoration of equipment.

PC-Optic-Sheet-Extrusion-Line.jpg)