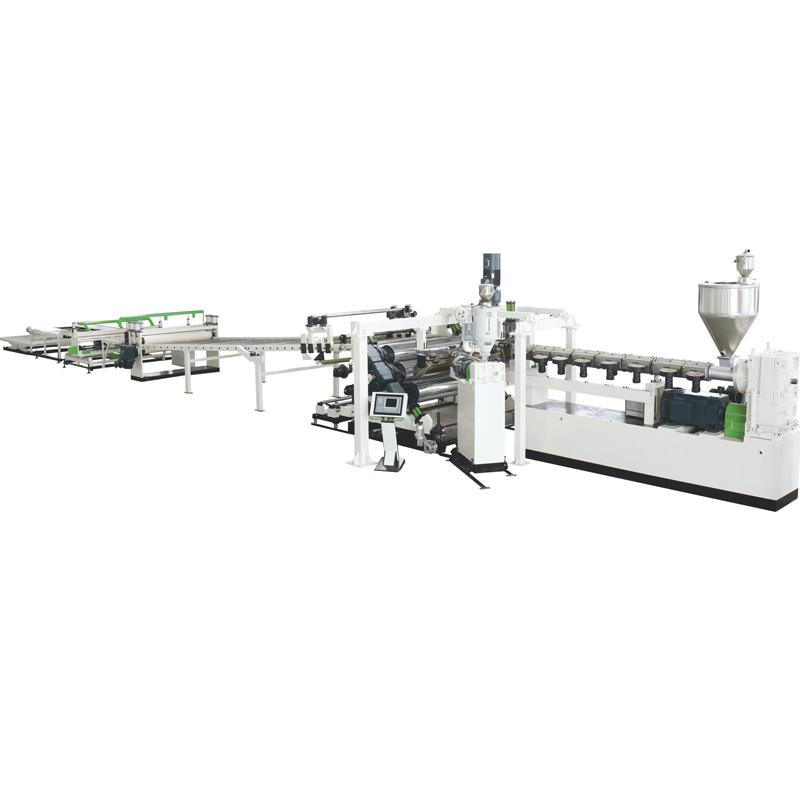

- Production line composition

Dwell has a unique process technology and equipment configuration, so that the TPU cast film production line successfully absorbed the industry attention and became one of the most popular models in the current market. The production line consists of the main components, including extrusion system, casting system, cooling System, traction cutting system and control System. Every individual component collaborates to achieve the function of producing TPU cast film.

- Extrusion system

The core of the whole production line is the extrusion system, mainly including extruder, screw, barrel, heating and cooling device. Dwell is equipped with a high precision, high stability extruder that can help keep TPU raw materials extruded evenly. The screw and barrel design fully takes into account the characteristics of TPU materials such as easy moisture absorption and shear sensitivity, so that the extrusion process can be smoothly carried out. The heating and cooling device makes the temperature of the extruder correct as per production requirements to ensure that the plasticization and melting effect of TPU is achieved.

- Casting system

The main components of the casting system would be a casting machine, a casting roller, a back pressure roller, etc. The casting machine spreads the TPU melt from the extruder evenly on the casting roller and results in a continuous sheet of TPU. The casting roller, as well as a new-style back pressure roller, are designed based on thorough consideration of the TPU material’s casting features (e.g. thickness and surface quality), so that the quality of TPU cast films can be ensured.

- Cooling system

The cooling system is very important because TPU cast film needs to be cooled and formed. Dwell: cooling system in general design uses water to spray or rapid air to blowing the heat. This system can be adjusted flexibly under the actual conditions of the production line to keep stably shape and size of TPU cast film in cooling process. The cooling mechanism, meanwhile, is energy-efficient and eco-friendly too because it consumes less energy and releases emissions in the production process.

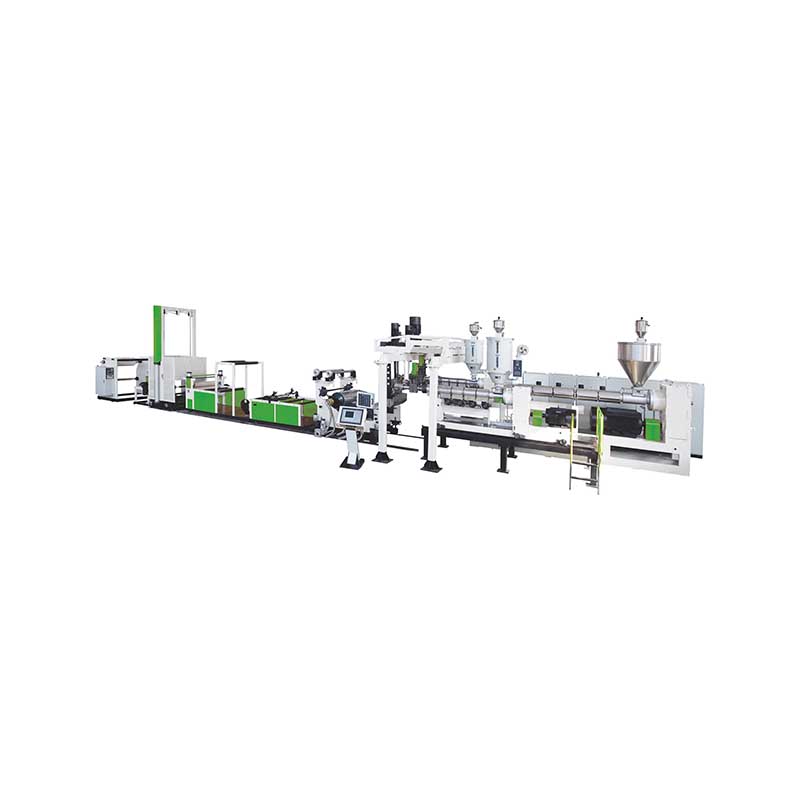

- Traction and cutting system

The traction and cutting system is mainly to draw the TPU cast film that has been cooled out of the cast roller, and accurately cut it. Typically, the system uses variable frequency speed regulation technology, which can be adjusted flexibly according to the specific requirements of the production line. The high-precision cutting blade is used to have the cut TPU cast film have an accurate size and a smooth edge.

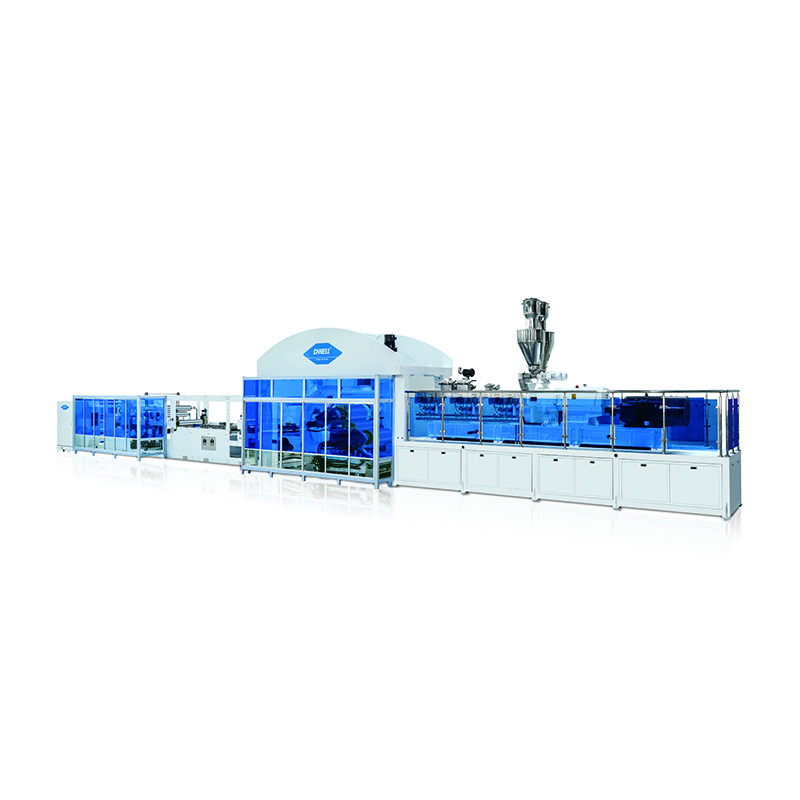

- Control system

Control System — The control system is at the center of the whole production line, and it monitors and controls different parts of the production line. Dwell will use control devices typically PLC or touch screen to achieve accurate, real-time control and adjustment of the extruder, cast device, cooling system traction and cutting system. It also has fault alarm and self-protection function of the control system. It will trigger alarm and bleeding to protect itself as soon as an abnormality is discovered in order to guarantee that the production line can run safely.

- Production Line Features

- High precision

The TPU cast film production line of Dwell is a high-precision and high-stability.【45†source】 Each link from the extrusion system to the casting system, cooling system and traction and cutting system is equipped with advanced equipment and process to guarantee high-precision manufacturing of TPU cast film. Simultaneously, the control system accurately controls and adjusts each part of the line further enhancing the accuracy and stability in production lines.

- High efficiency

This production line uses an automatic intelligent production method, which significantly improves the production efficiency. The mass transfer links include the extrusion system, casting system, cooling system and traction and cutting system, which have achieved automatic control and adjustment with little manual intervention and waiting time. Meanwhile, the fast mold change and fast adjustment functions have also been developed for this production line, which can be quickly switched and adjusted according to different production needs, further enhancing its efficiency.

- High quality

Dwell’s TPU cast film production line has greatly improved the advanced process technology and equipment configuration, therefore ensuring the upscale quality of TPU cast film. TPU cast film produced through all links of the production line to carry out strict quality control and testing, ensure that TPU cast film has good physical properties and appearance quality. Meanwhile, the production line additionally possesses waste recycling and reuse function which further enhances resources utilization rate and products quality.

- Saving energy and protecting the environment

The requirements of energy saving and environmental protection are fully taken into account in the design and production process of this production line. Overall equipment on the production line uses energy-efficient technology and-recycling materials to curb energy usage and emissions. Meanwhile, its production line has waste recycling and recycling function to recycle and treat the waste produced in the production process, so as to further improve resource utilization rate and environmentprotection performance.

III. Benefits of the production line

- Customized production

Dwell’s TPU cast film production line is customizable for customers. It can be customized as per the requirement of the customer i.e., thickness, width or color. Such personalized production can not only meet customer needs, but also enhance the market competitiveness of the product.

- Intelligent control

It has an advanced intelligence control system that achieves accurate control and adjustment of the production process. The operating status and other parameters of the production line can be monitored in real time through the control system. As soon as it detects an abnormal situation, it will give out an alarm signal and approach the shut down for protections. Meanwhile, control system also can automatically adjust and optimize production of need to realize the high degree automation and intelligent swept in a sentence line.

- Perfect after-sales service

Dwell cares about customer service and post-sale support. It has a professional after-sales service team, which can provide customers with technical support and maintenance services at any time. In addition, the company also provides some value-added services such as on-site training and operation guidance for equipment to facilitate customers’ better use and maintenance of the production line.

- Application fields

Dwell TPU cast film production line has extensive applications for its TPU cast film. TPU cast film has wide application prospects in high-end packaging, medical dressings, building materials, advertisements and transportation fields due to its excellent properties of high strength and impact resistance low temperature / boiling water resistance; chemical and corrosion resistant; anti-aging performance.

- High-end packaging

It is widely used in all levels of packing, especially high-end packing which may use TPU cast film. It is used in making various high-end packaging materials, such as food packaging, pharmaceutical packages and etc. because it is having great flexibility and transparency. Meanwhile, TPU cast film has excellent sealing and moisture resistance, which can effectively prevent the items in the package from being affected by the external environment.

- Medical dressings

Another big area for TPU cast film is medical dressings. Attributable to its good elasticity and air permeability, it can be applied for some different sorts of medical that include as injury dressing, band‐help et cetera. MeanwhileTPU cast film has excellent antibacterial property and chemical resistance. which is very strong to inhibit wound infection and cross infection.

- Construction field

TPU cast film is extensively used in the construction field too. It is used to manufacture various building materials, including soundproof doors and windows, skylights etc., due to its good weather resistance as well as chemical resistance. TPU cast film mode at the same time has good transparency and flexibility, can be used in a variety of building decoration materials and partition materials to make.

- Advertising industry

TPU cast film can be applied to the advertising industry, including light boxes, signs and other advertising materials Due to its excellent flexibility and transparency (reporter), TPU cast film can meet the various advertising needs of different shapes and colors.

- Transportation industry

TPU cast film also is available in several end user industries especially in transportation sector which can be used for making vehicle doors, windows, windshields and other automotive components. It protects the safety of vehicles and passengers due to its high impact resistance and chemical resistance.

TPU-Casting-Film-Production-LINE.png)